Mola Assembly Tips

Expert Guidance for Seamless Building Experiences

Get the most out of your

Mola Structural Kits

Welcome to our Assembly Tips page, where you'll find a comprehensive and ilustrated collection of tips and best practices designed to help you get the most out of your Mola Structural Kits.

Learn how to handle and store components, apply loads in different ways, combine sets for expanded possibilities, and understand the unique magnet behavior that connects the pieces of the system.

Elevate your building experience with detailed instructions and insights, ensuring your Mola performs at its best.

(You can also find some of these instructions in every Mola Structural Kit book/manual)

![]()

Mola products contain small magnets and it's not a toy.

Keep Mola parts away from children, pets and magnetically sensitive items.

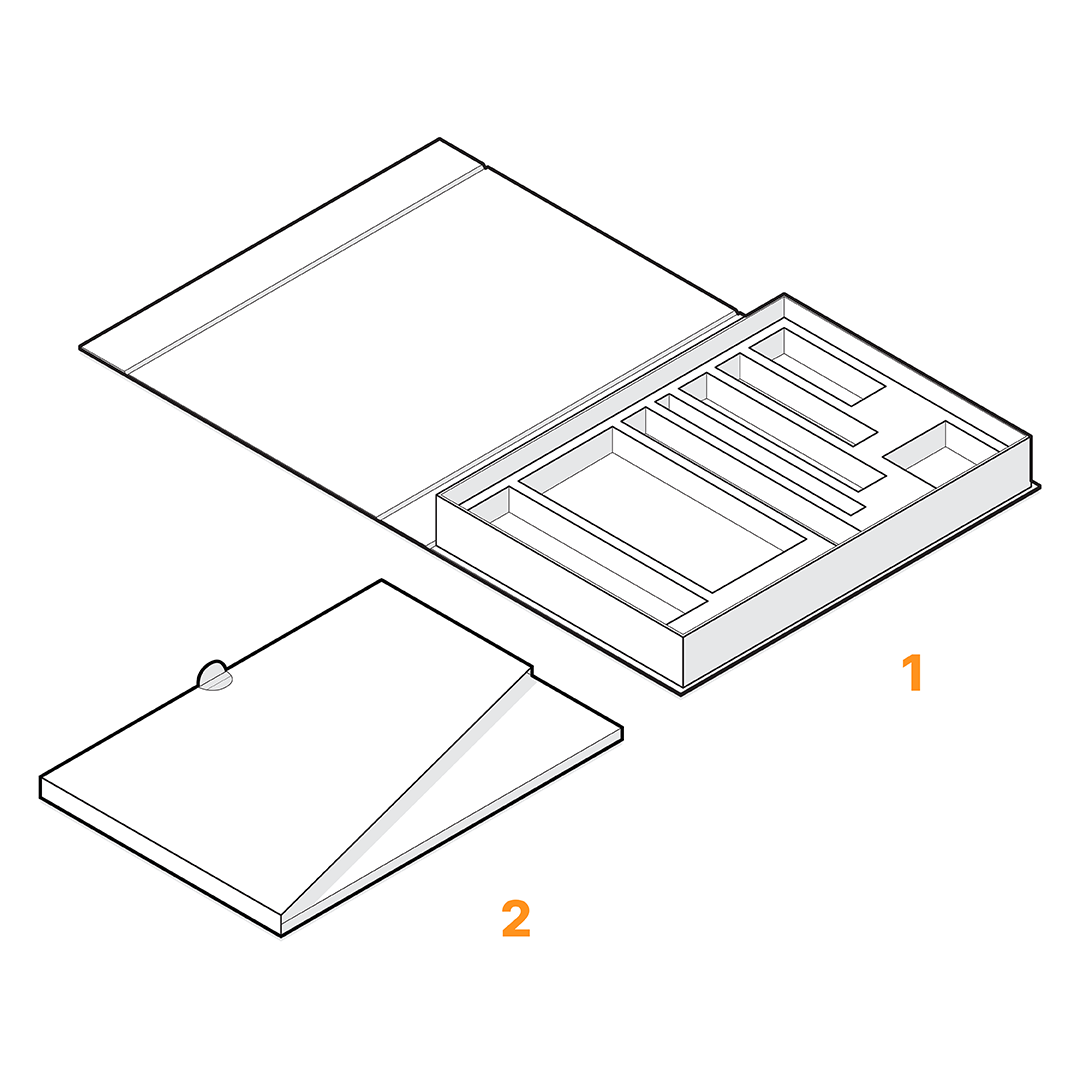

Storage Items

Mola Structural Kit Box

Mola Box

Mola Structural Kits are packed in a rigid and compact box. With a paper and foam construction, resembling the feel and appearance of a book, it surprises with its resistance and durability. This ensures the product stays protected and organized, all in a compact design you can place on your shelf or slip into your backpack to take it anywhere.

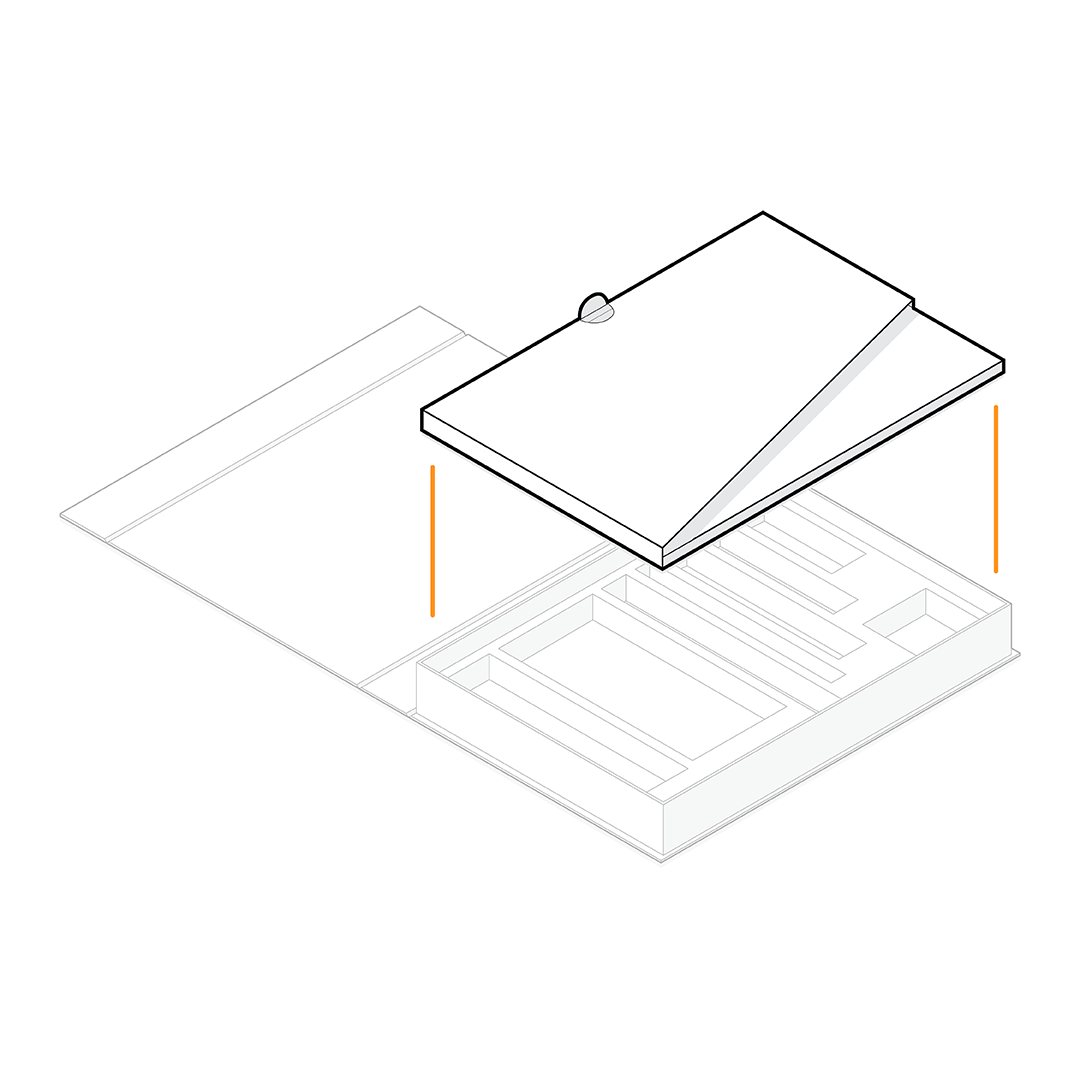

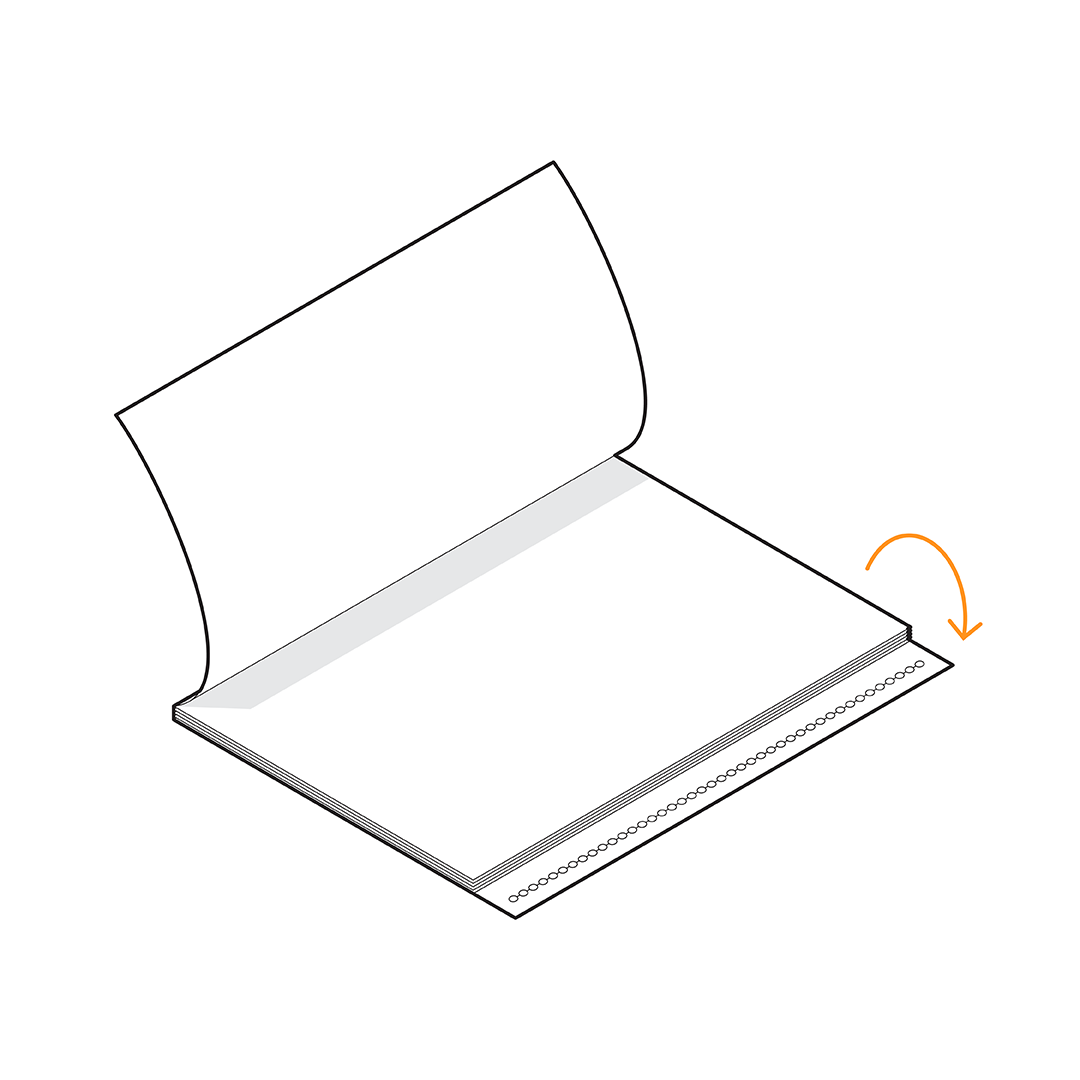

Box Closure Instructions

Always place the folder inside the box before closing it! The folder not only holds the Ground Plate and the book/manual but also plays a crucial role in keeping the set components in their specific inserts. If the folder is not placed inside the box, the components may shift or fall out of their designated spaces during transportation and storage.

Handling Components

Learn about the unique magnet behavior that connects the pieces of the Mola Structural System.

This useful information will help you organize and store the components properly.

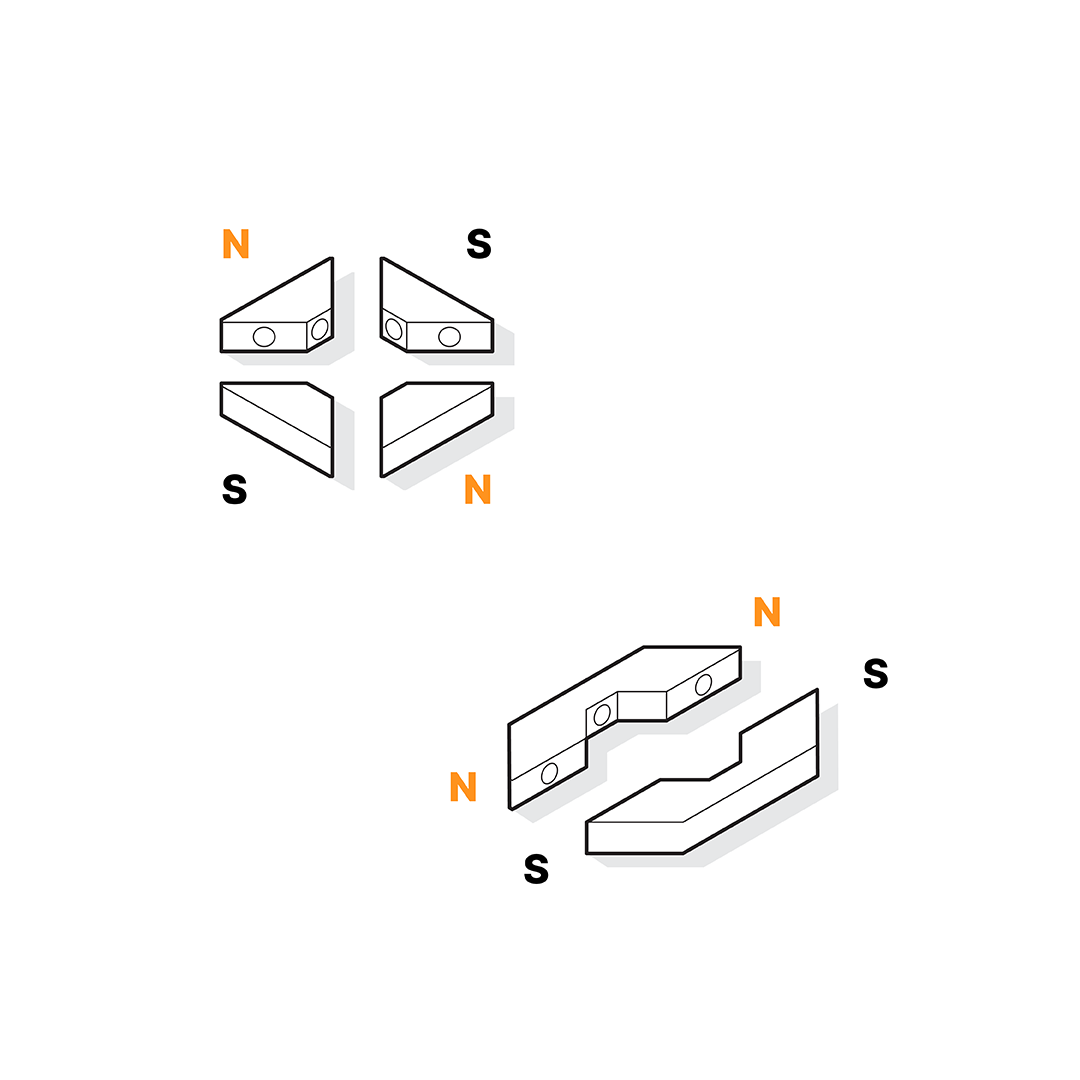

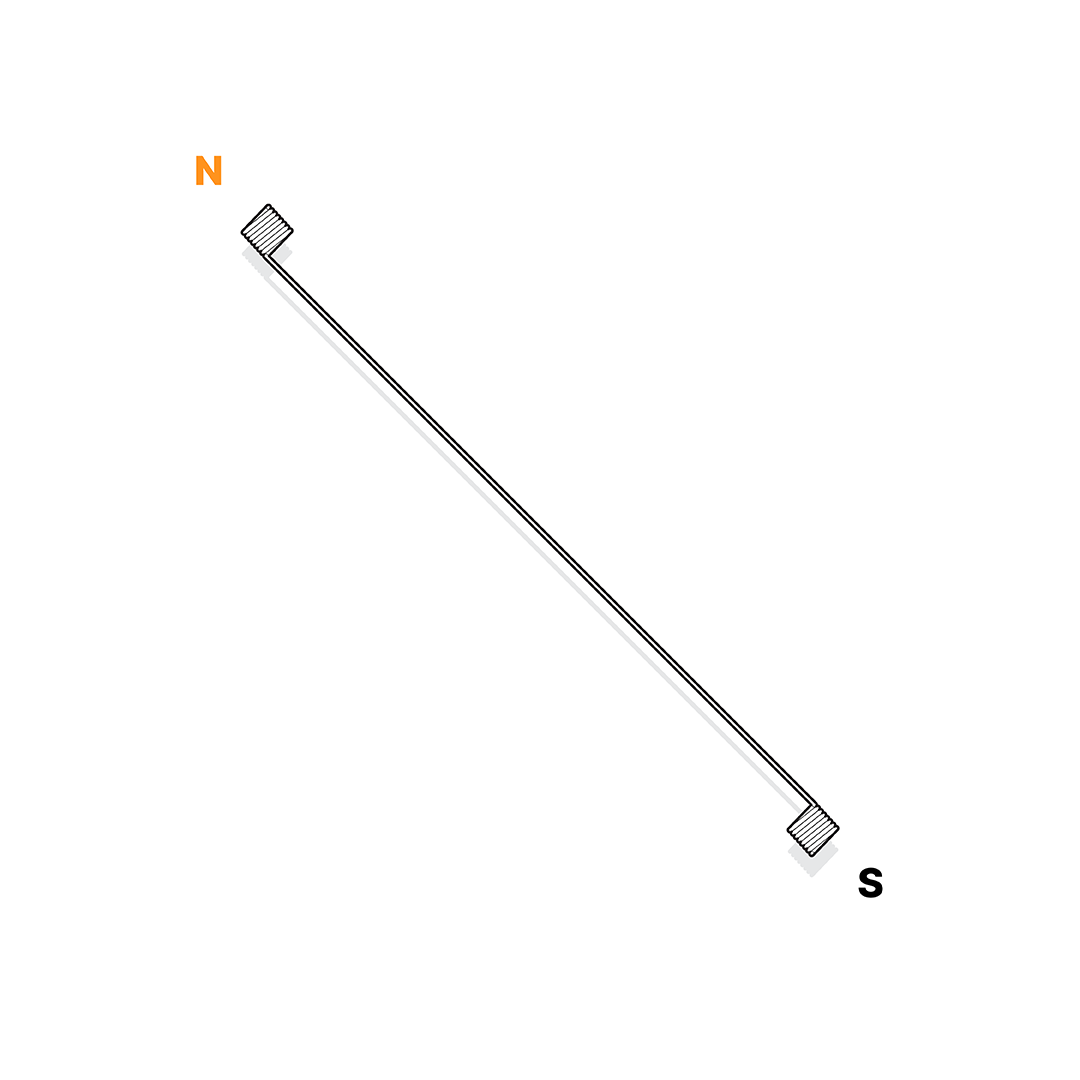

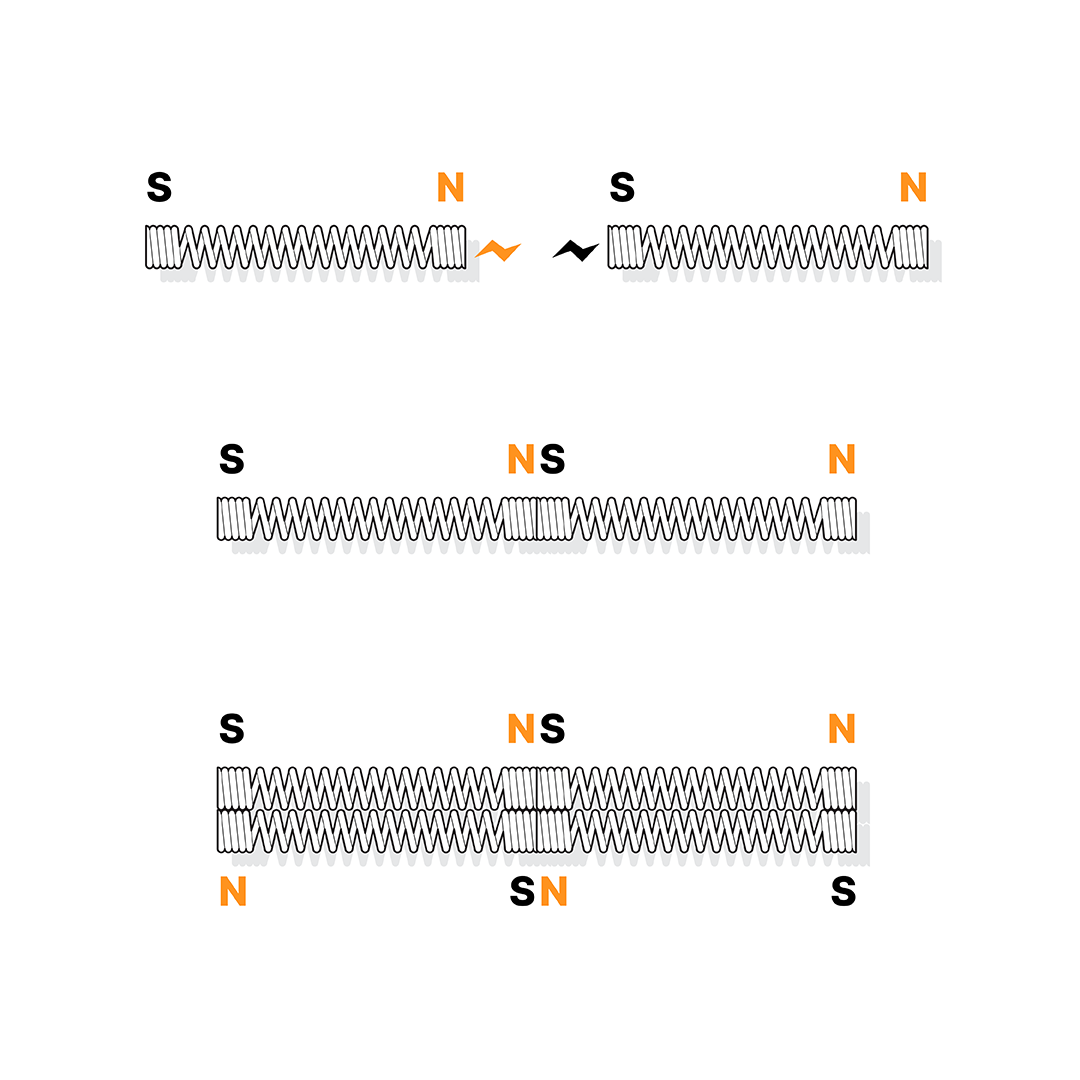

Bars and Diagonals

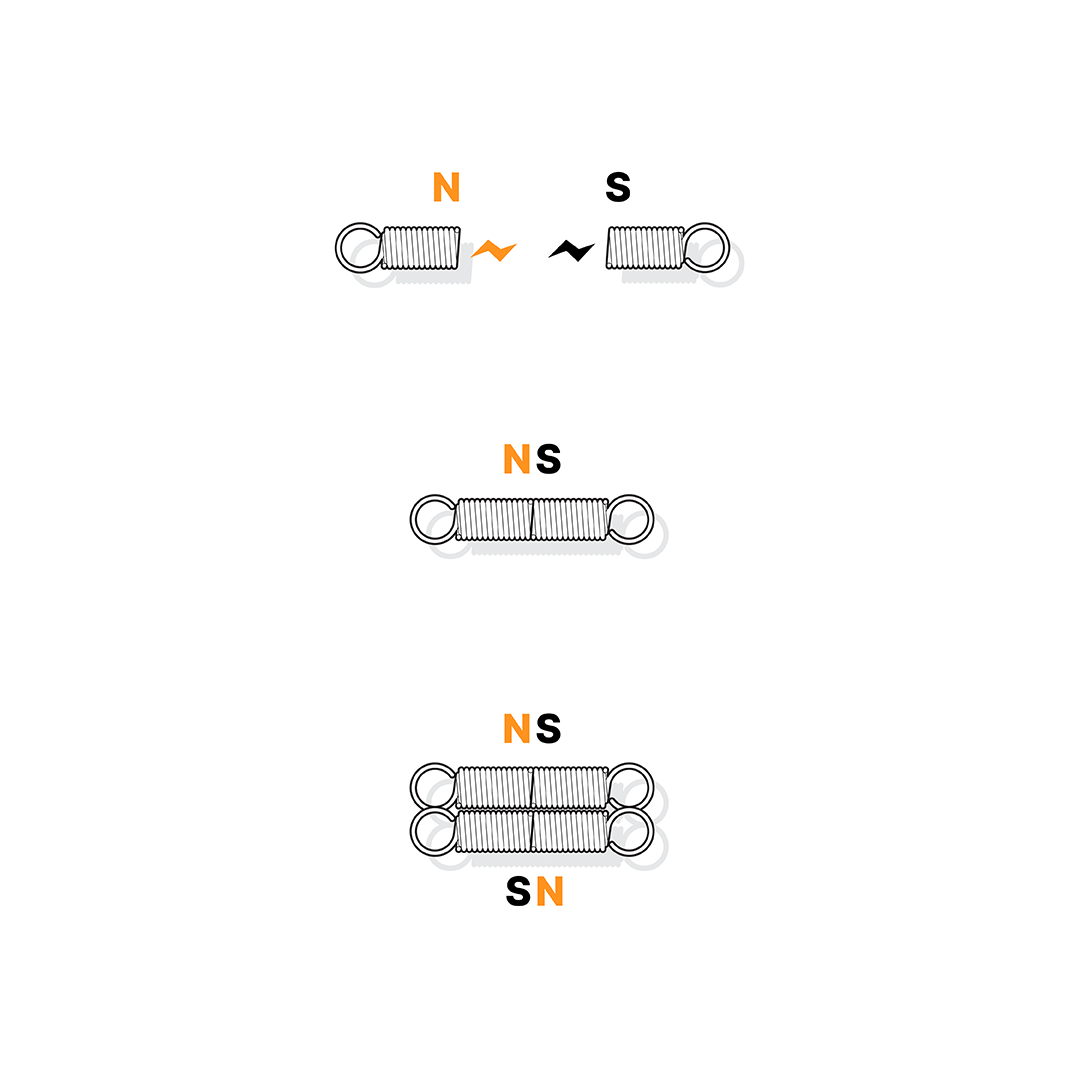

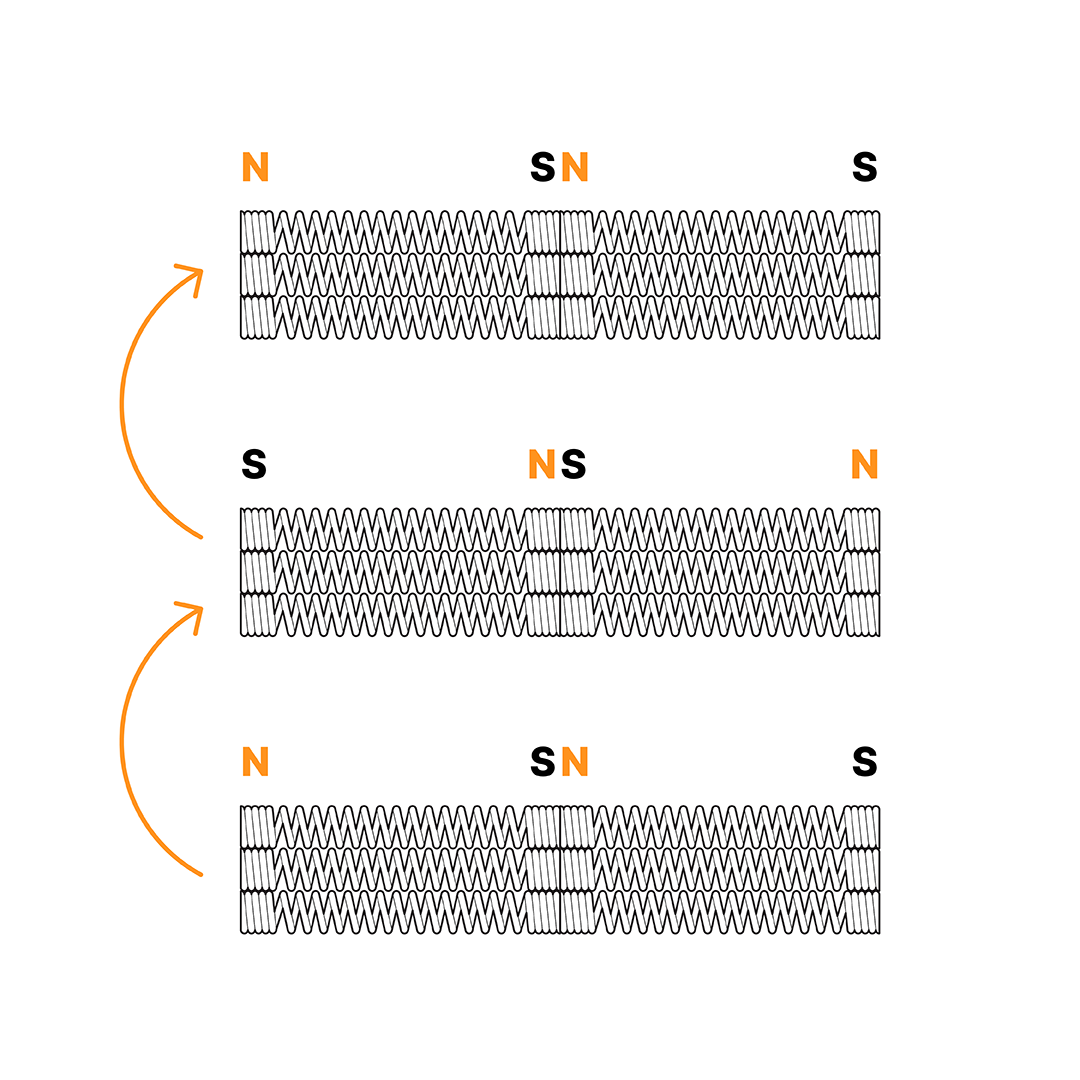

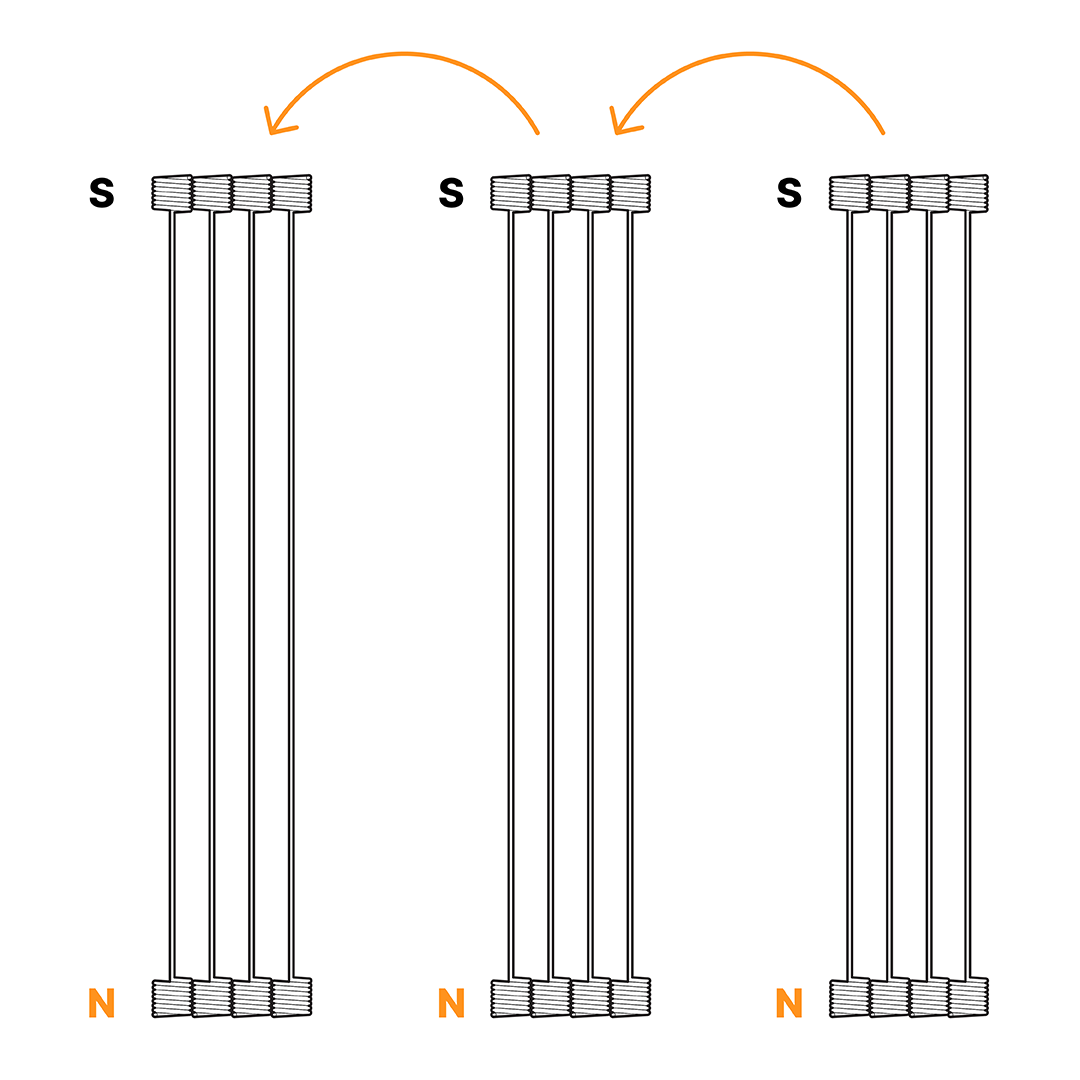

The Bars and Diagonals have magnets at their extremities and these magnets are positioned so that the parts may connect to one another. Thus, each bar or diagonal has ends with opposite magnetic polarity (N, north pole, and S, south pole). Therefore, if there is repulsion between two parts, simply invert one part to perfectly connect them.

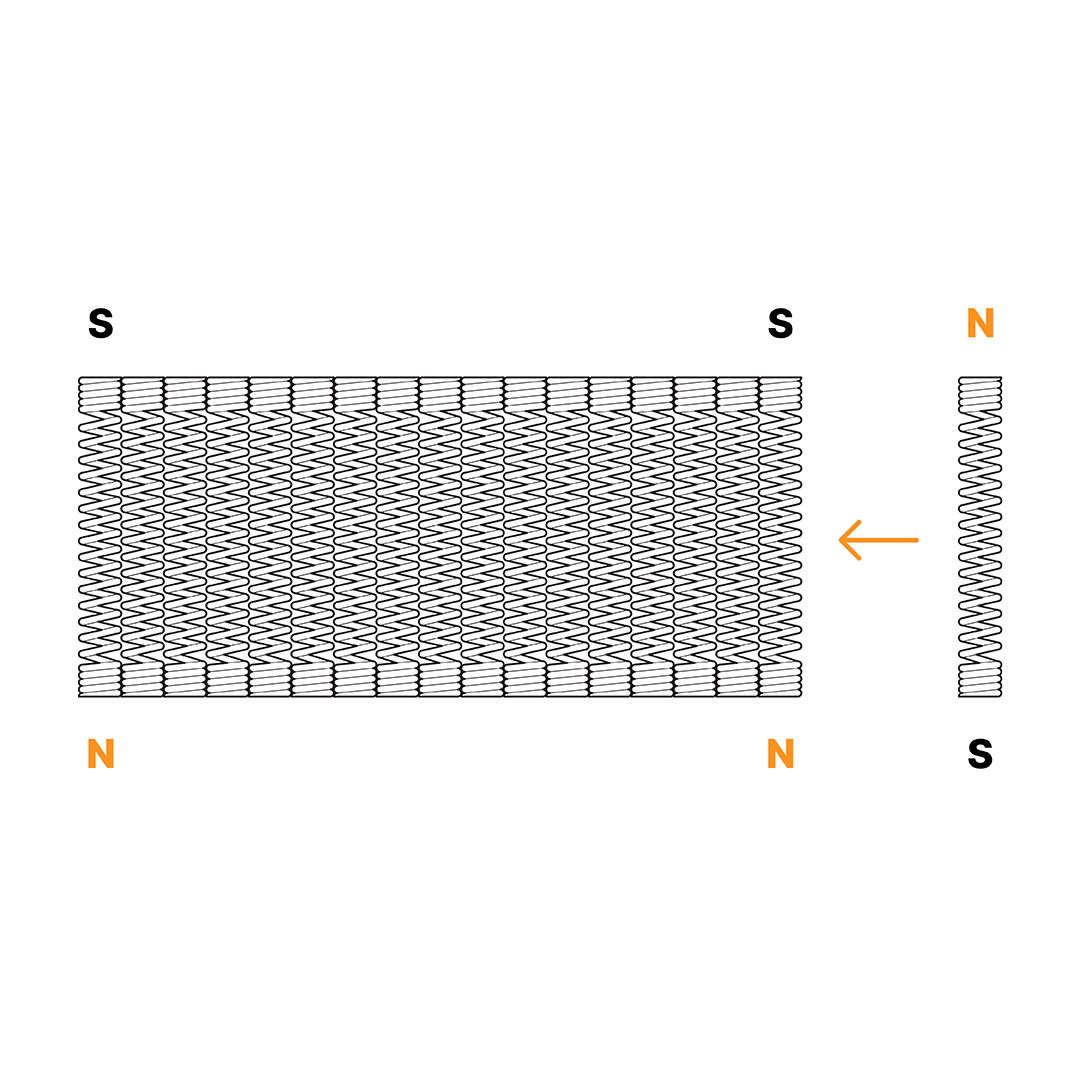

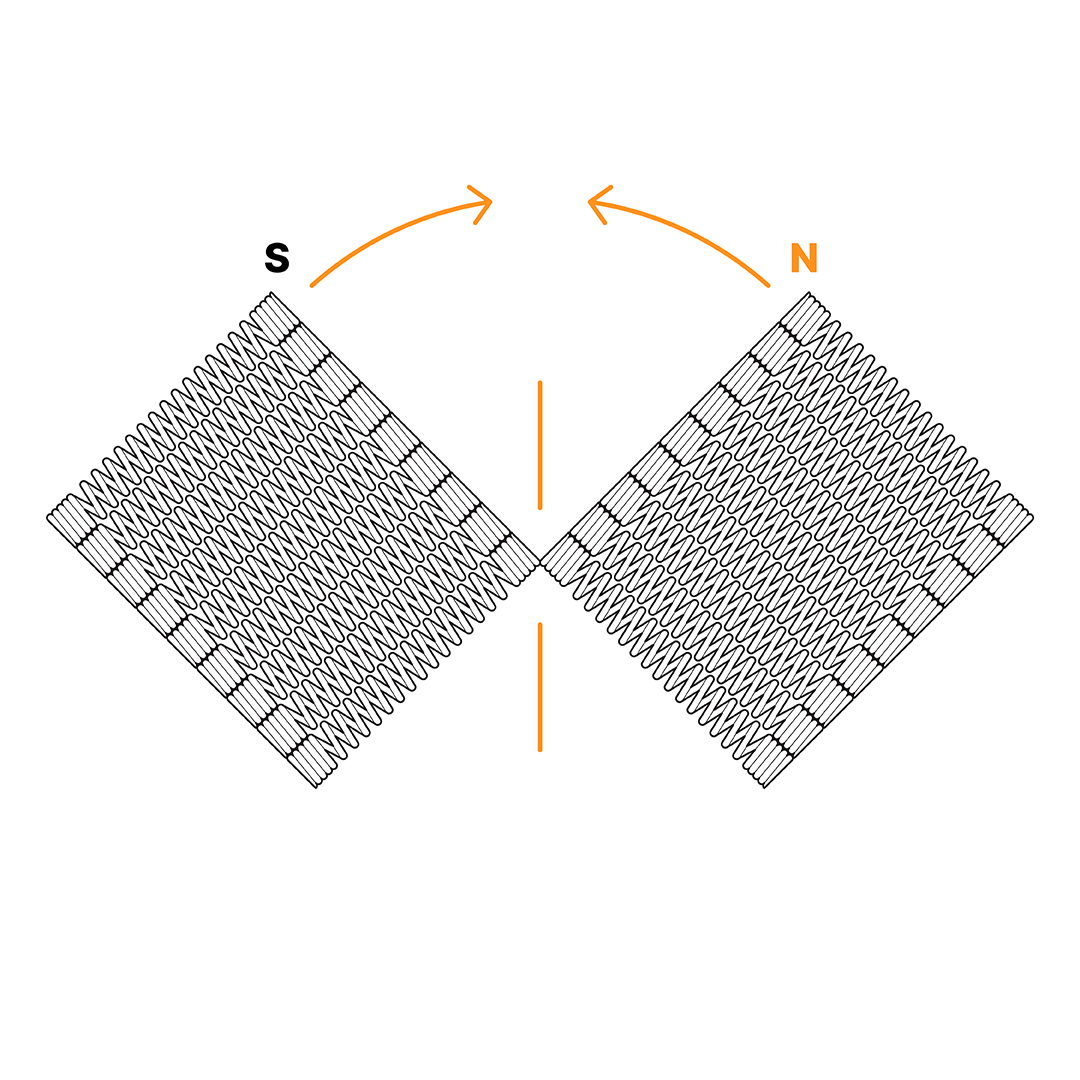

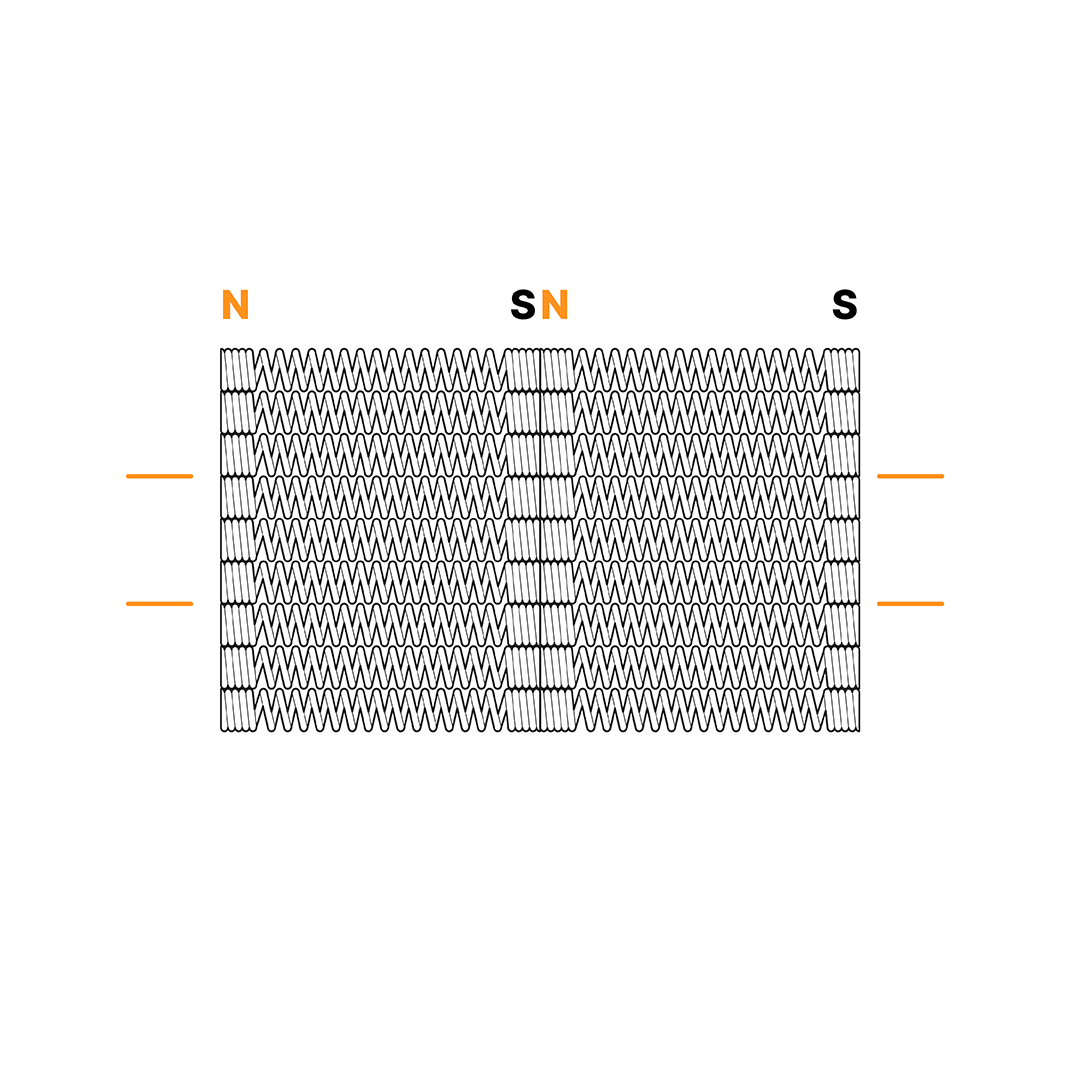

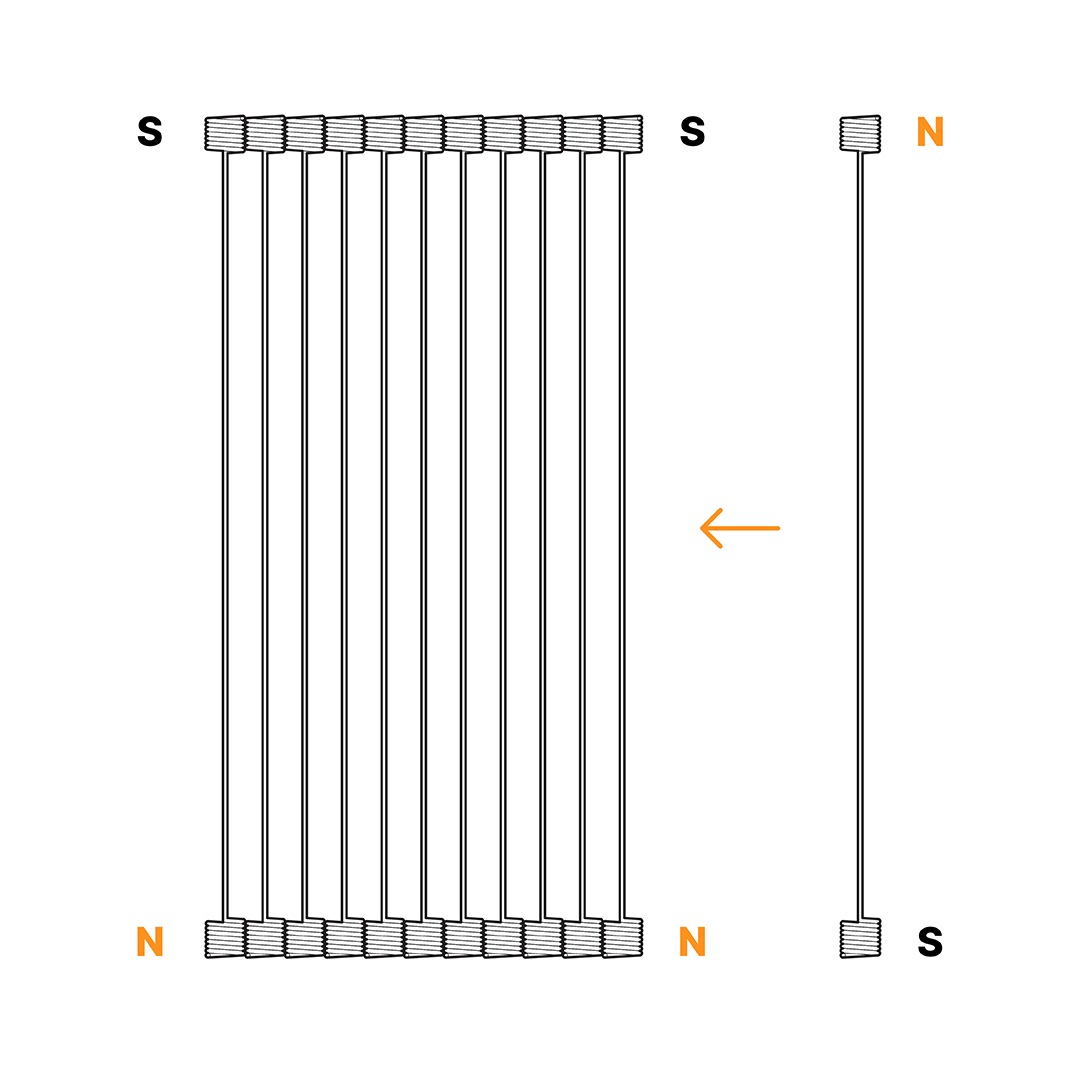

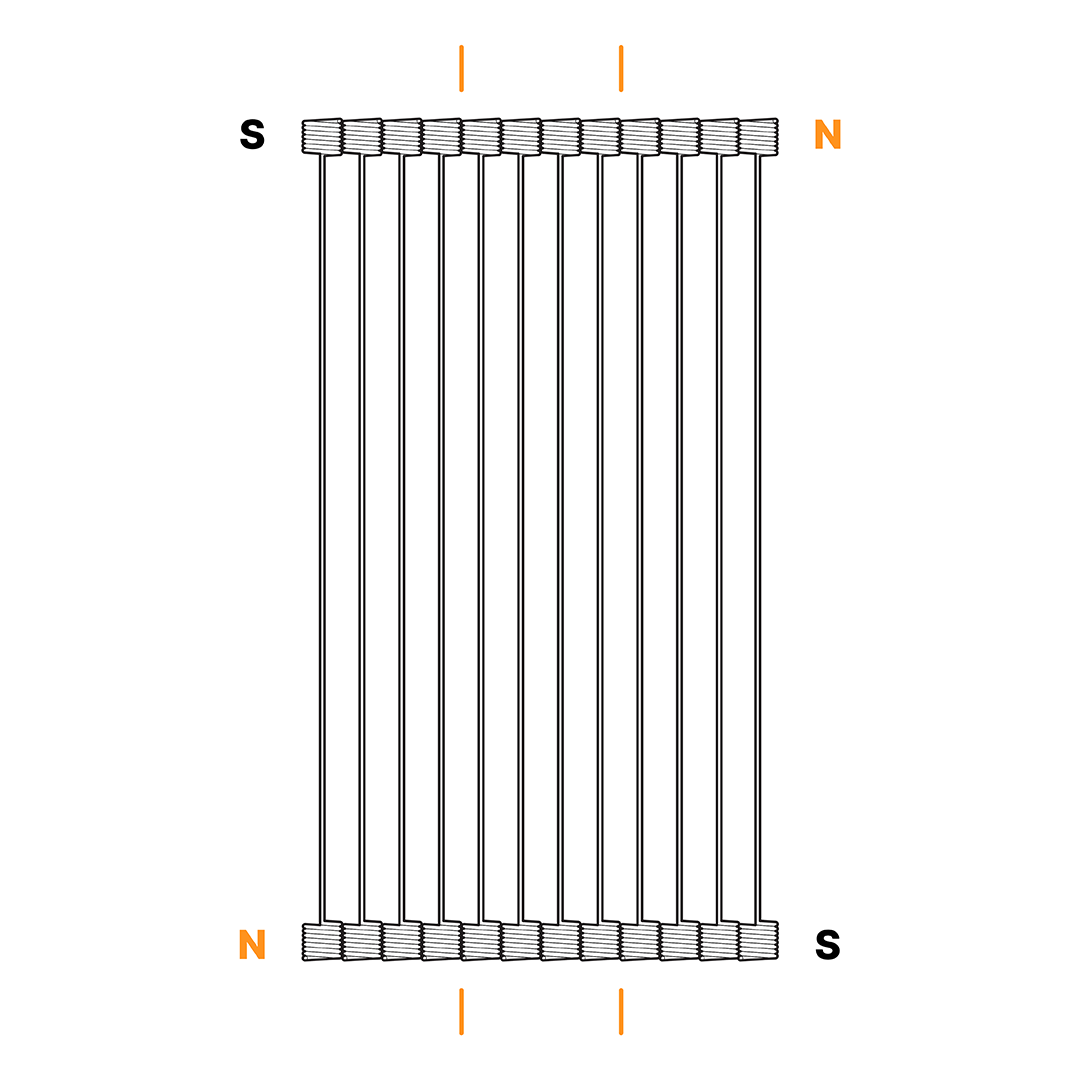

Handling and Storing Bars and Diagonals

A step-by-step guide to master the organization and storage of bars and diagonals in the box.

This procedure will work for all bar and diagonal elements, regardless of their length.

By following these steps, you can ensure all components will be neatly stored and ready for use.

Assembly and Load Application

Useful information for using Mola 1, Mola 2, Mola 3, and Accessories.

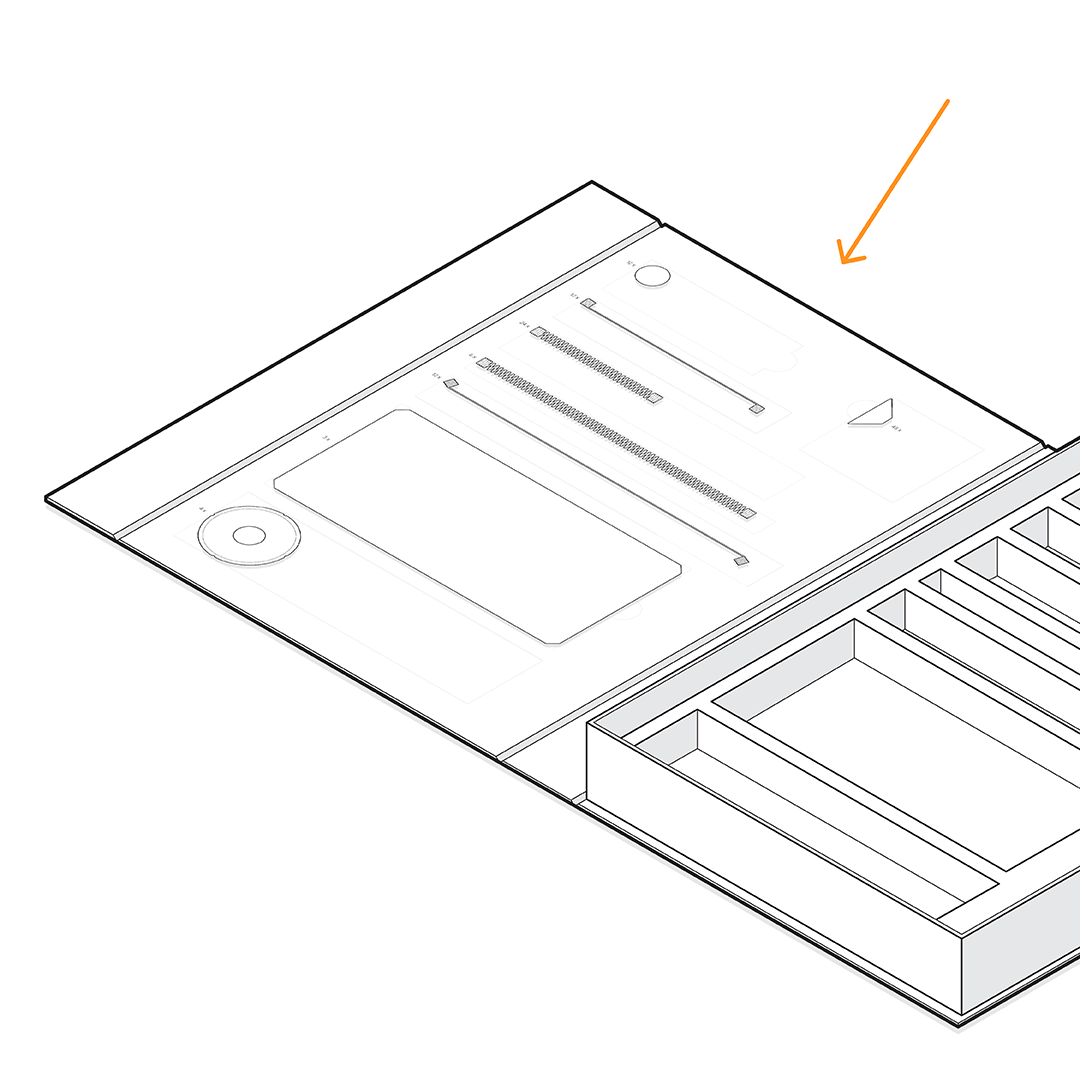

Ground Plates

Learn the characteristics of the ground plates and their connection with other components.

Following this guidance will help you achieve an accurate and precise foundation setting-out process.

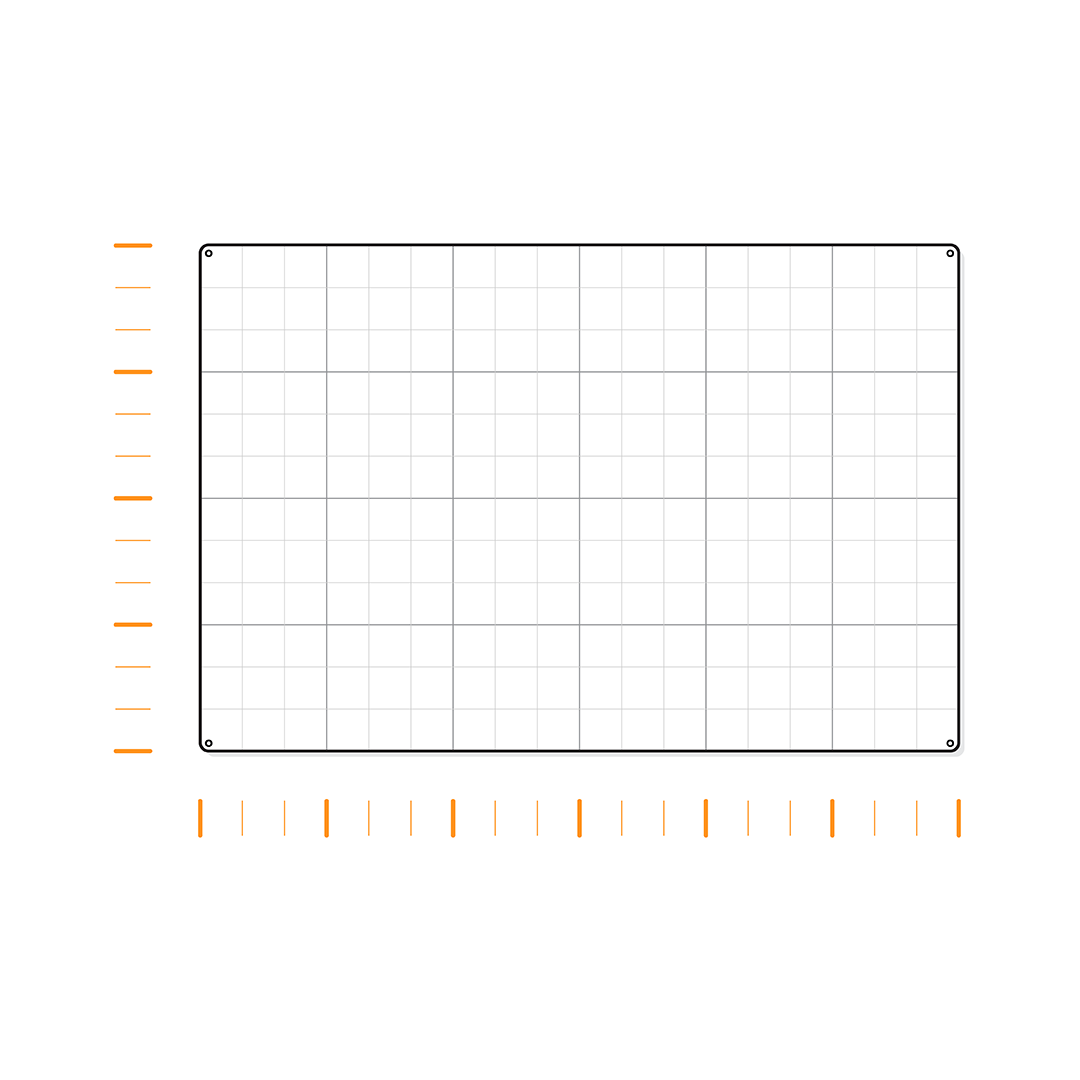

Structural Axis Marks

The Ground Plate represents the ground of a real building. It is designed with line marks that highlight the structural axis of the system.

These lines are not just for aesthetic purposes - they play a key role in ensuring that all components align perfectly, maintaining the structural integrity of your assembly.

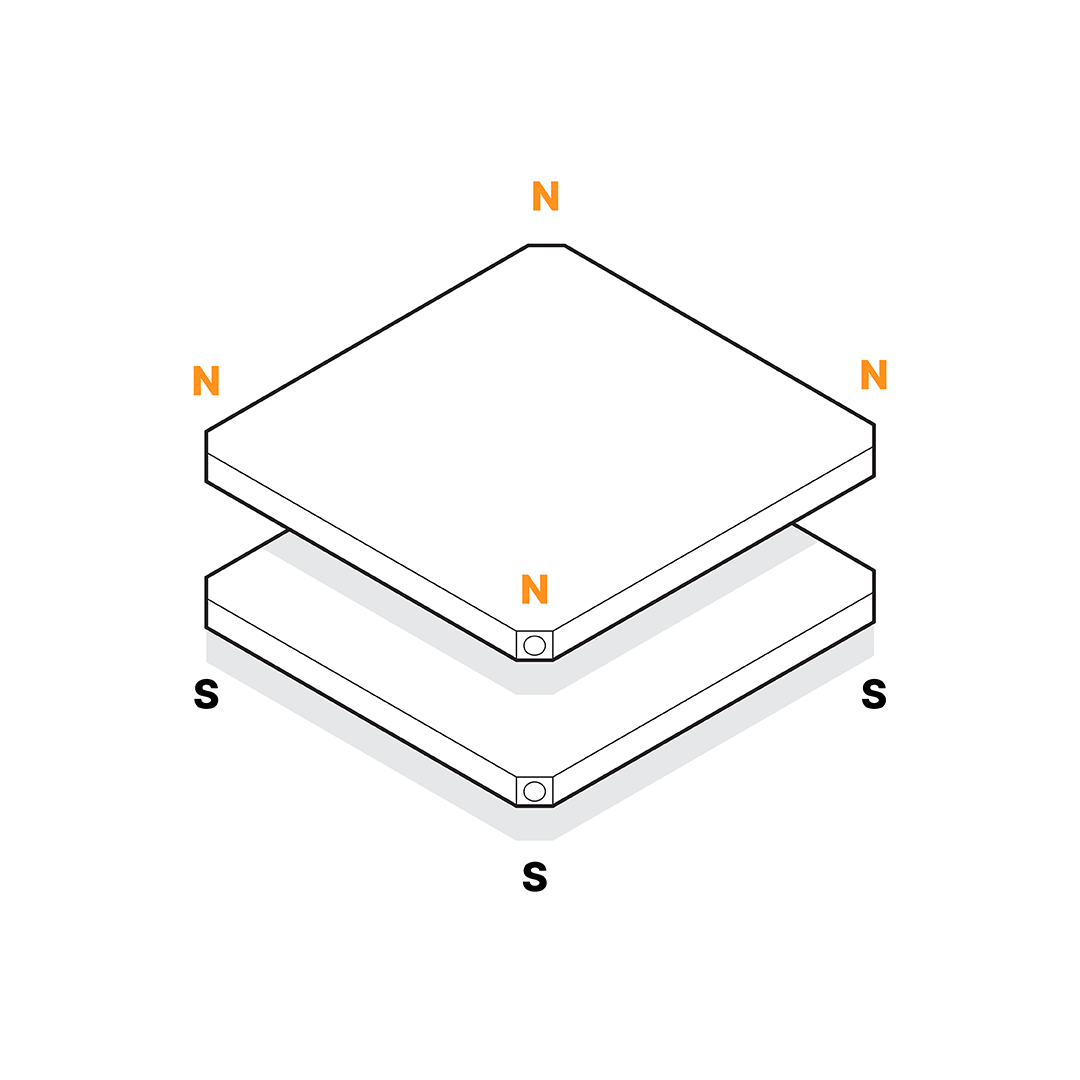

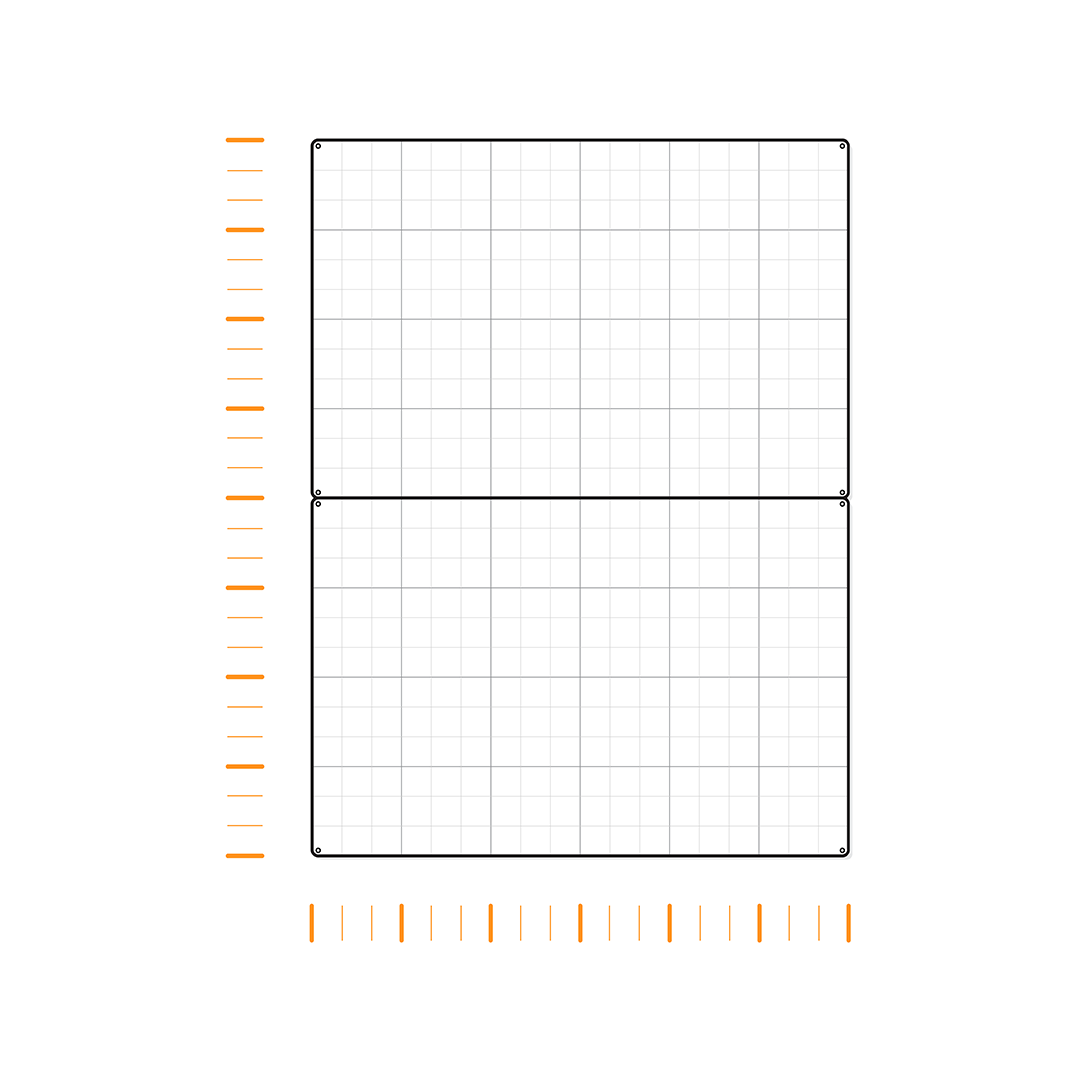

Expanding the Building Area

Combine two or more Ground Plates for a larger building area. Ensure the axis marks of each plate are aligned. This will maintain the modularity of the system, providing a seamless and precise extension for your design.

You can use regular masking tape underneath the Ground Plates to fasten them together.

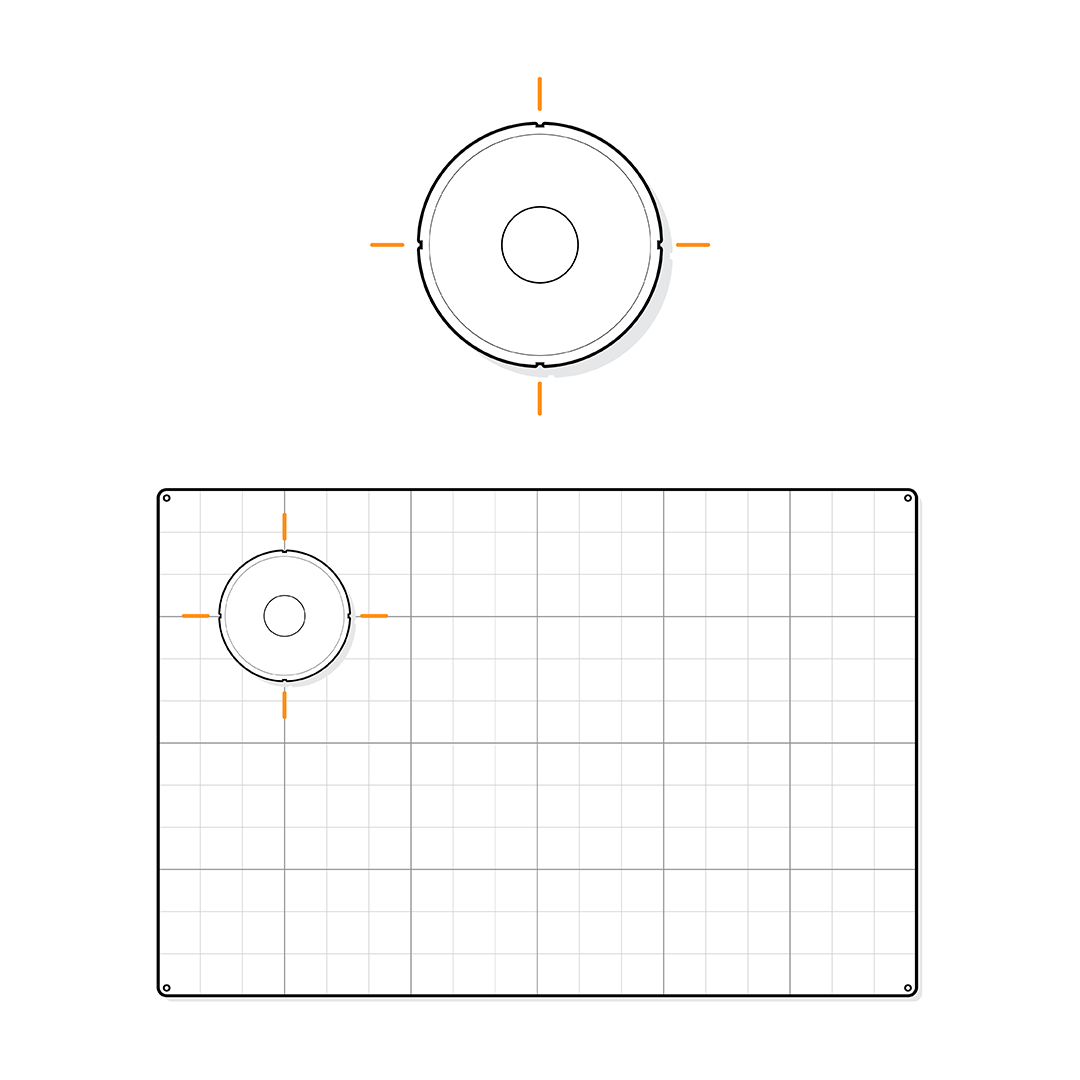

Ground Connections

The Ground Connection acts as the foundation of a building, connecting the structure to the ground. Each Ground Connection has four lateral axis markings for proper alignment and positioning.

Align its lateral markings with the axis marks on the Ground Plate. This ensures that the component is correctly positioned, providing a precise foundation for your building.

Setting Out Foundations

All components of the system are designed based on the structural axis modulation. By aligning different components, such as bars, with these axis marks on the Ground Plate, you can accurately determine the correct positions for the structure's foundations.

This setting-out procedure will function as the process of transferring dimensions from a drawing plan to the actual construction site.

Mola Structural Kit 3

Learn about the characteristics of some components in the Mola Structural Kit 3.

Follow these tips to build your cable structures with greater precision.

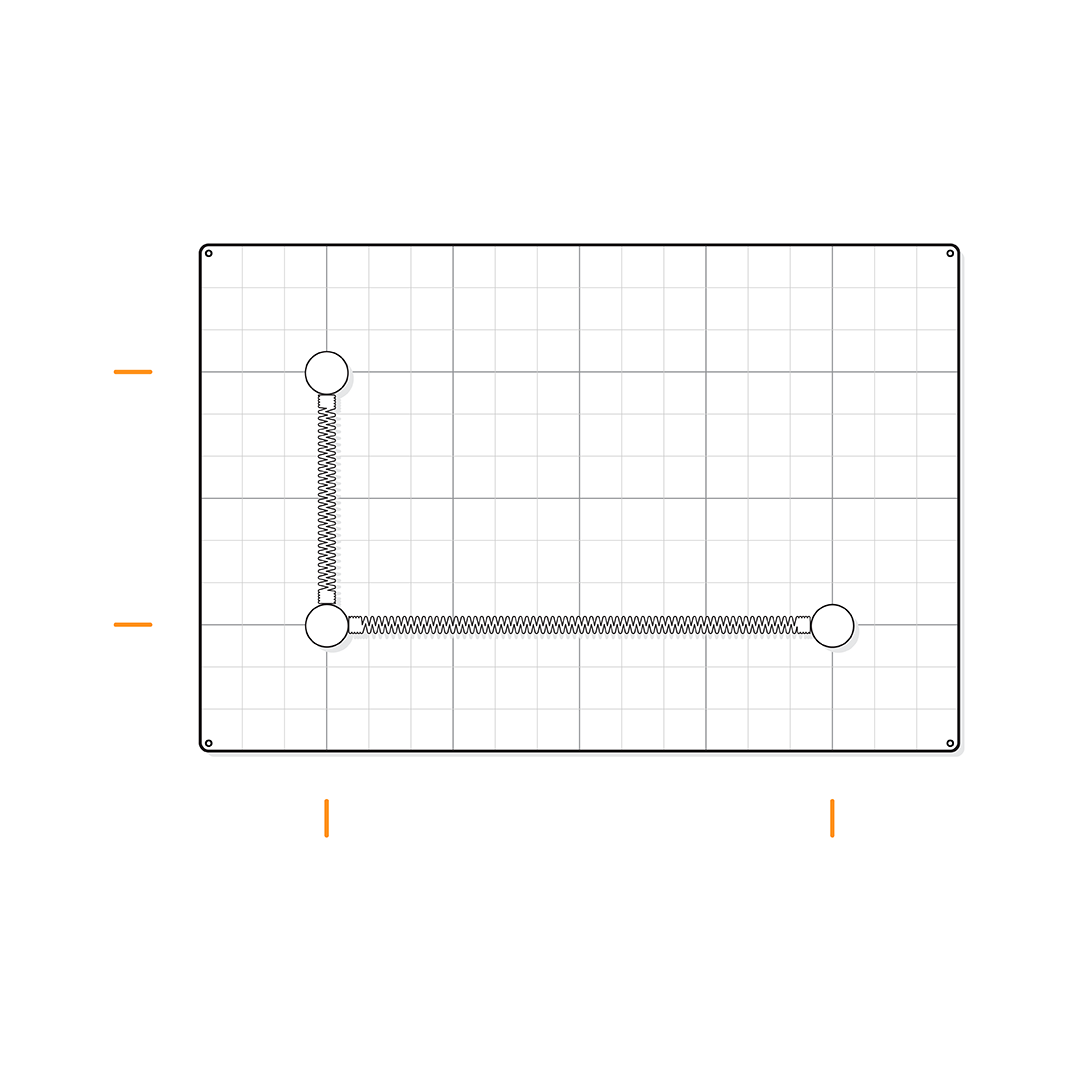

Measuring Cables

In the Mola 3 book/manual, specific cable lengths are suggested for each example of structural systems to be assembled.

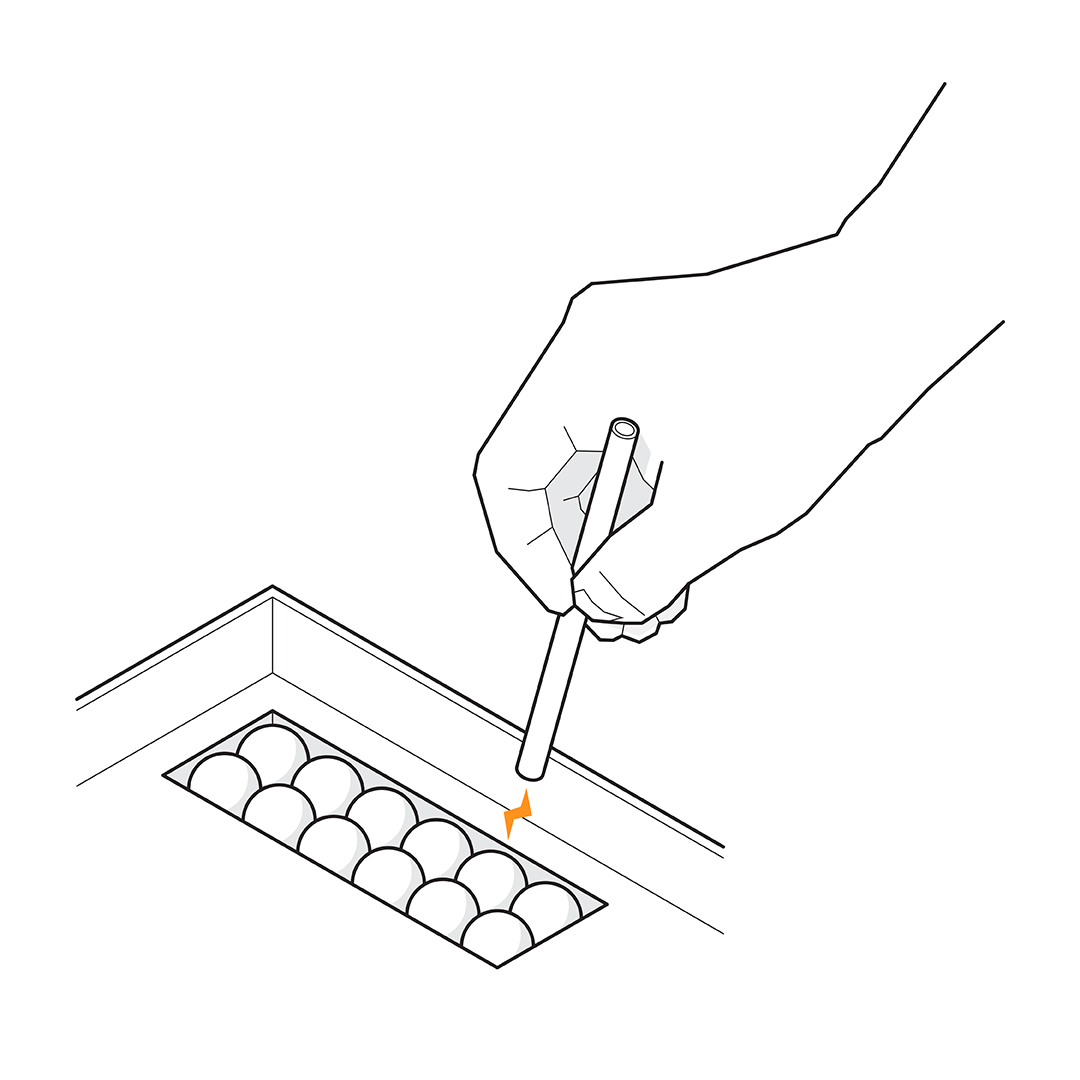

Use the cable measurement ruler located on the back cover to measure the exact length of the cable, taking into account the number of balls, without having to count them one by one.

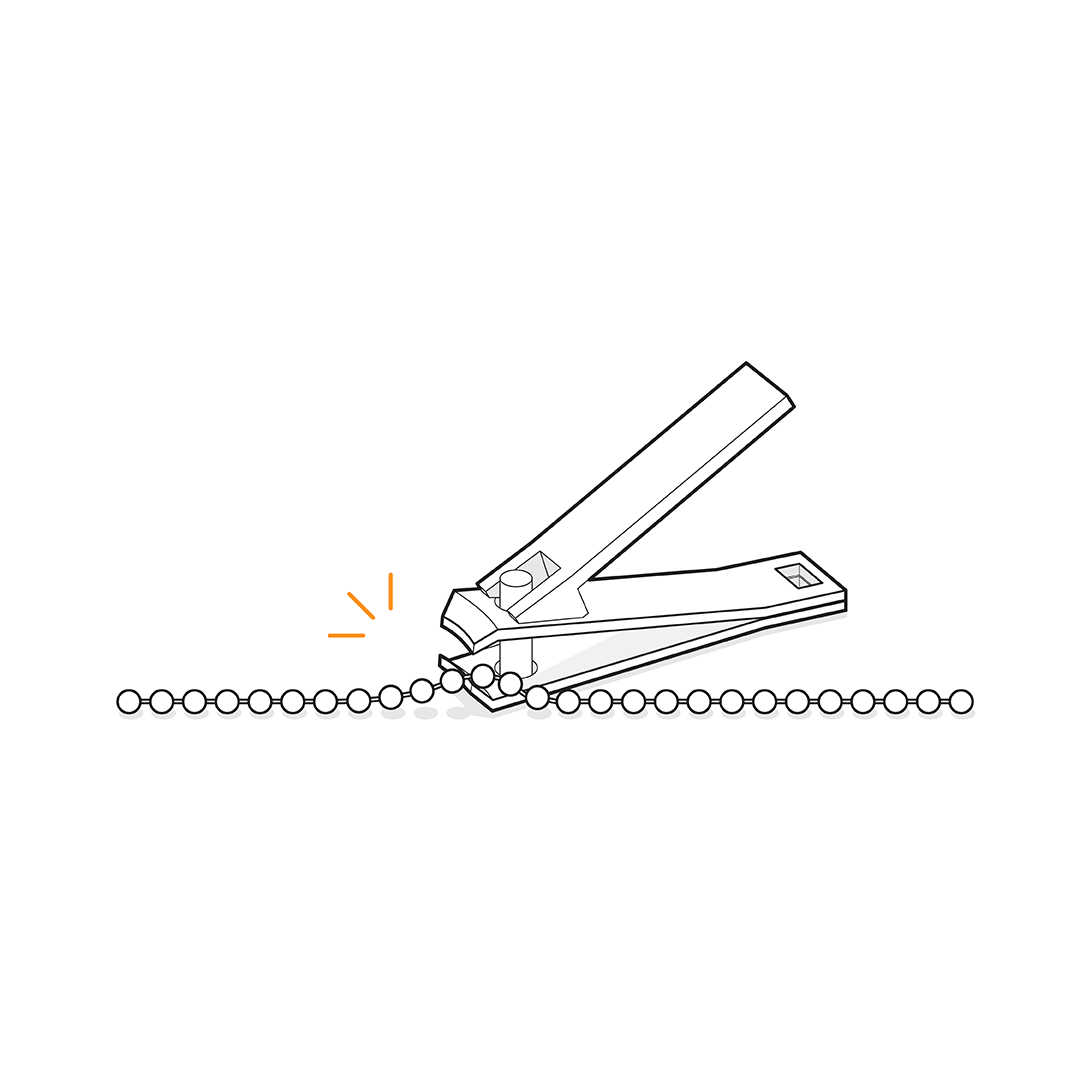

Cutting Cables

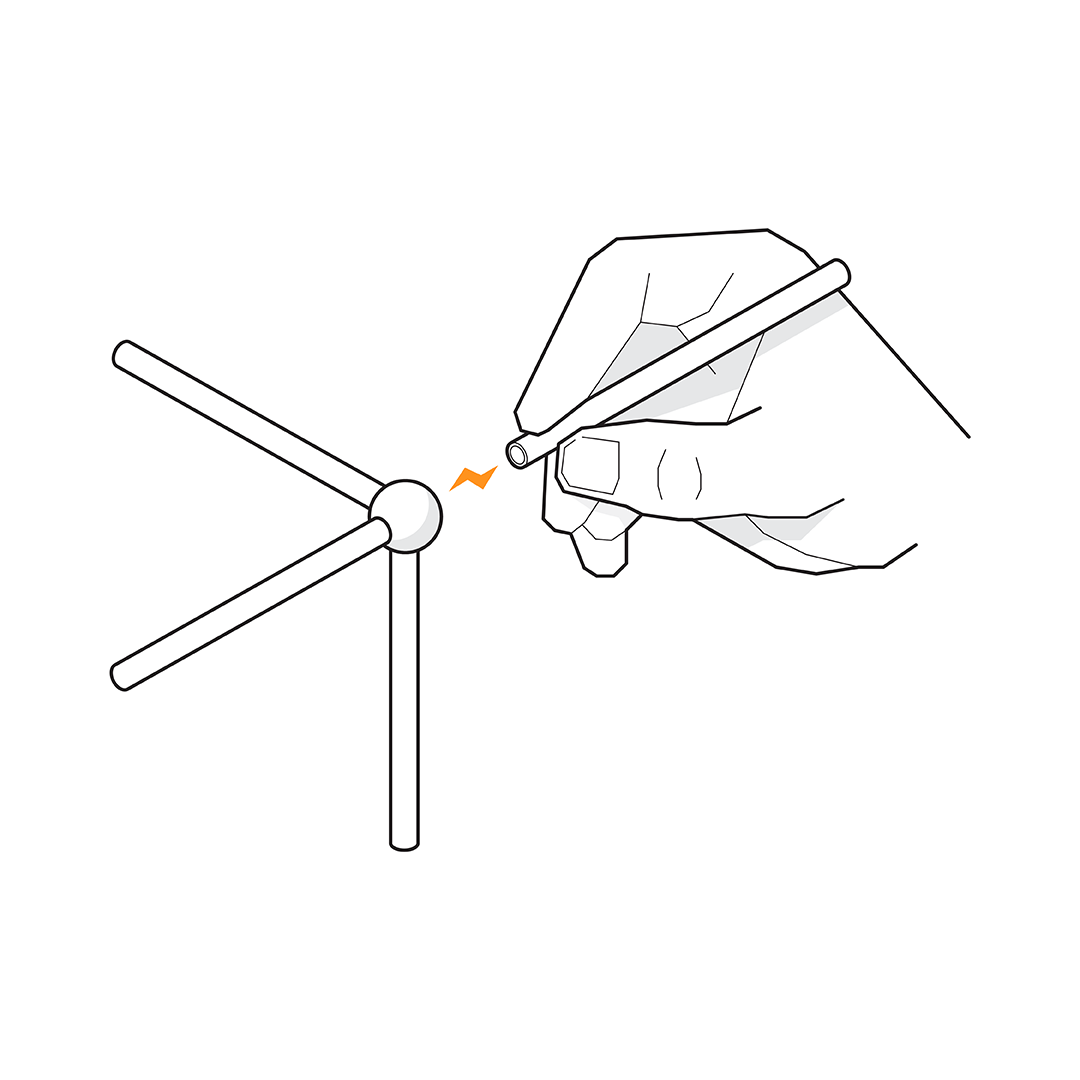

Use the cutting tool to trim the cable to your desired length. Before doing so, check if you already have cables of the same length from previous use. This way, you can make better use of the cables, enabling you to assemble all the structures presented in the book/manual.

If needed, you can also order Cable Replacement Parts from our online store >

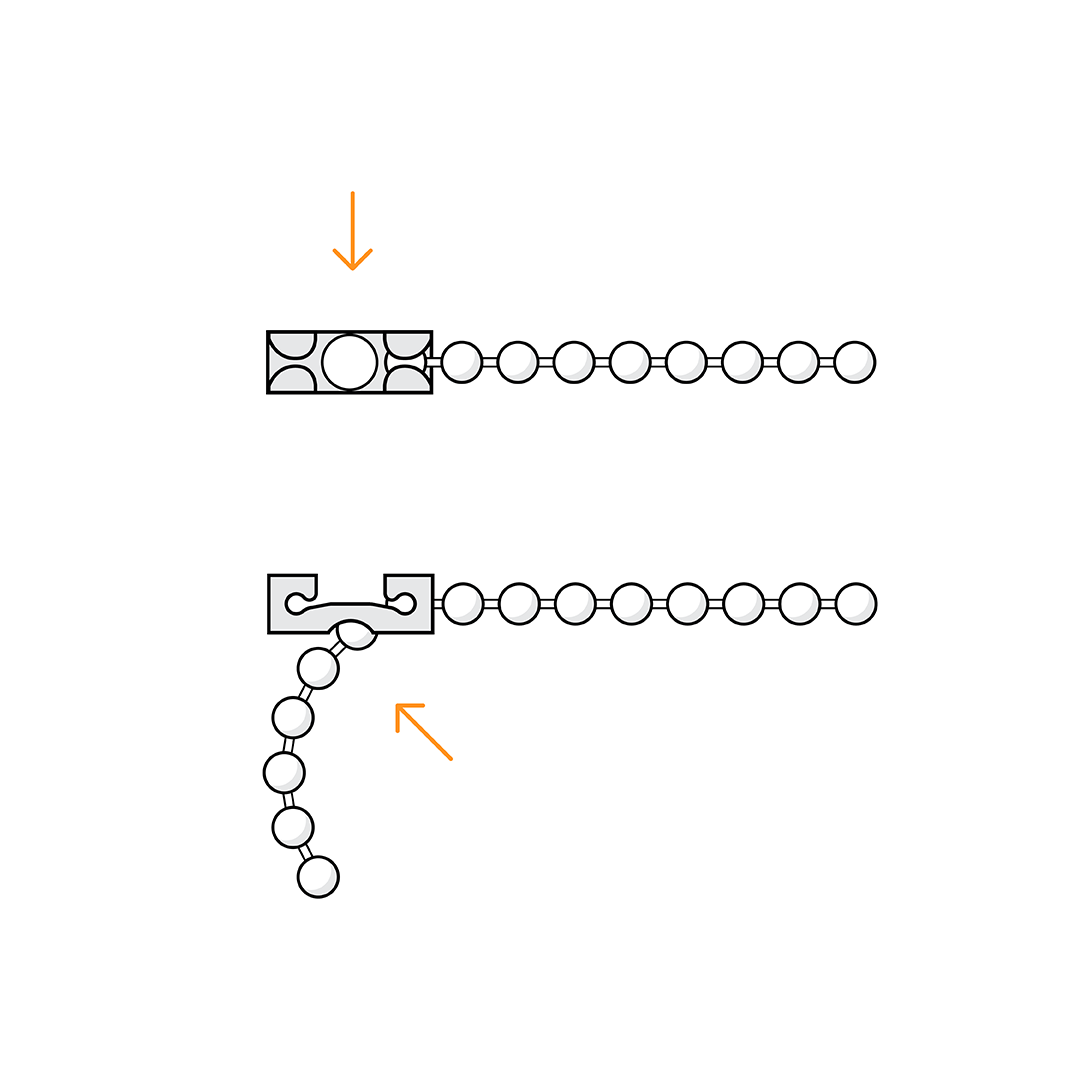

Cable Clip

The attachment of cables to the Mola Structural System involves combining various connection elements.

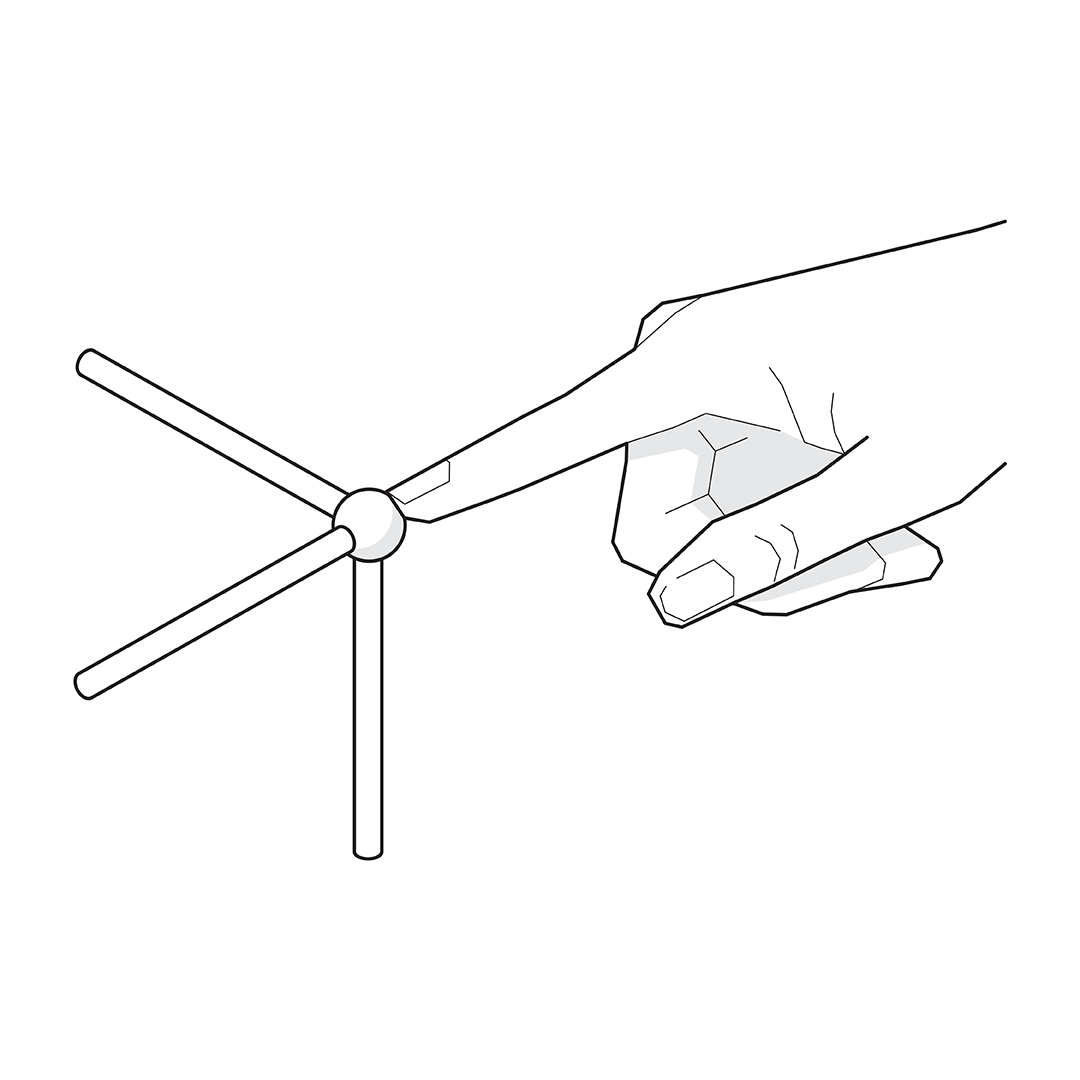

The Cable Clip features a central hole that allows connection to any ball along the cable, not just the end. This versatility eliminates the need to cut the cable to precise lengths for assembly. Simply leave a portion of the cable outside the Cable Clip to facilitate structure assembly.

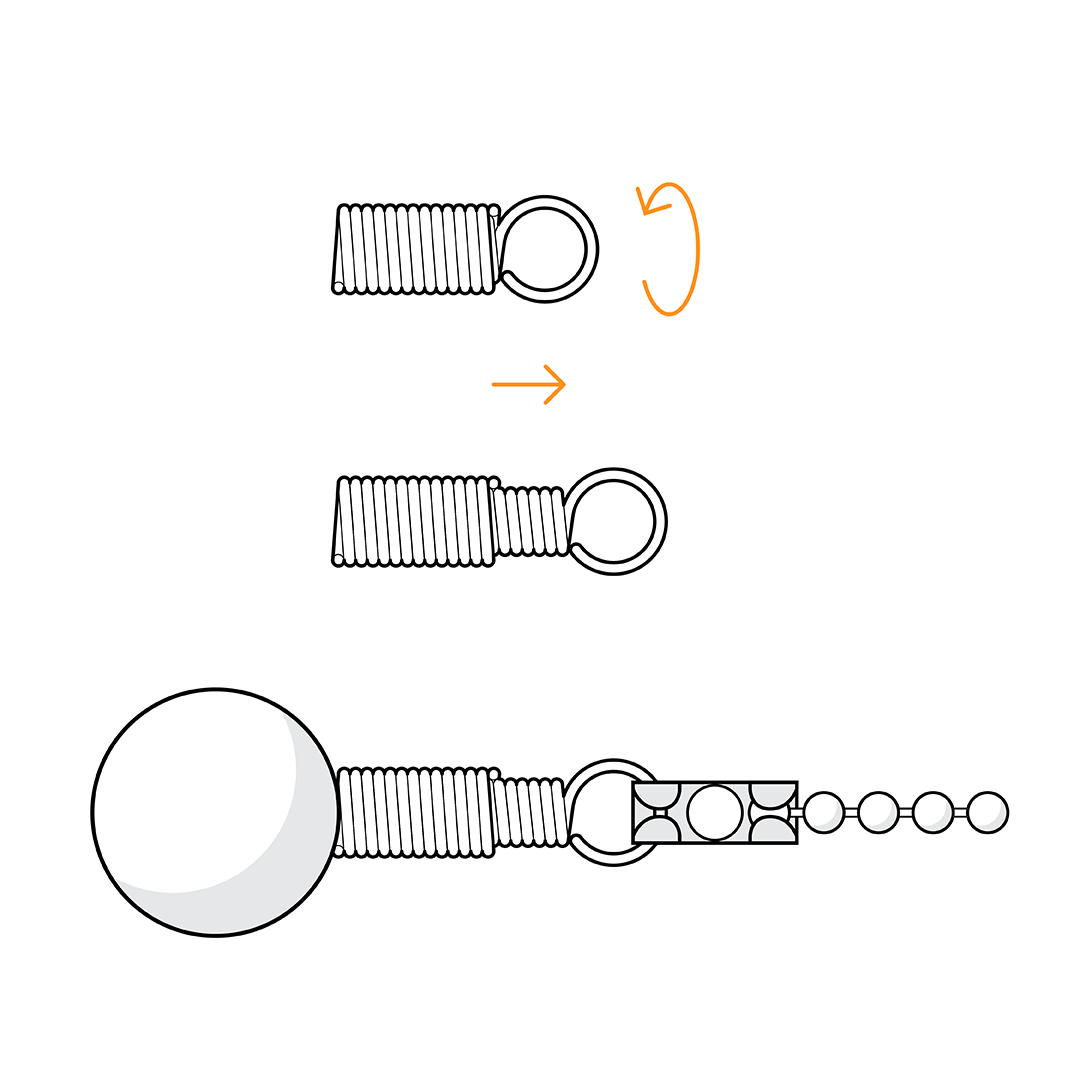

Cable Connection

The Cable Connection is crucial for attaching cables to the system. It has two threaded-together parts: the external part with a magnet for attaching to the structure and the internal part with a ring for connecting the Cable Clip. It also functions as a tensioner, allowing you to make final adjustments to the cable length and maintain proper tension. Simply hold the magnet part and twist the ring part to make the cable longer or shorter, ensuring a precise assembly process.

We’d love to hear from you!

Share Your Assembly Tips

Share your tips and tricks for using Mola and help others build better.

Your insights and experiences can inspire and guide our community.