The Science Behind Mola

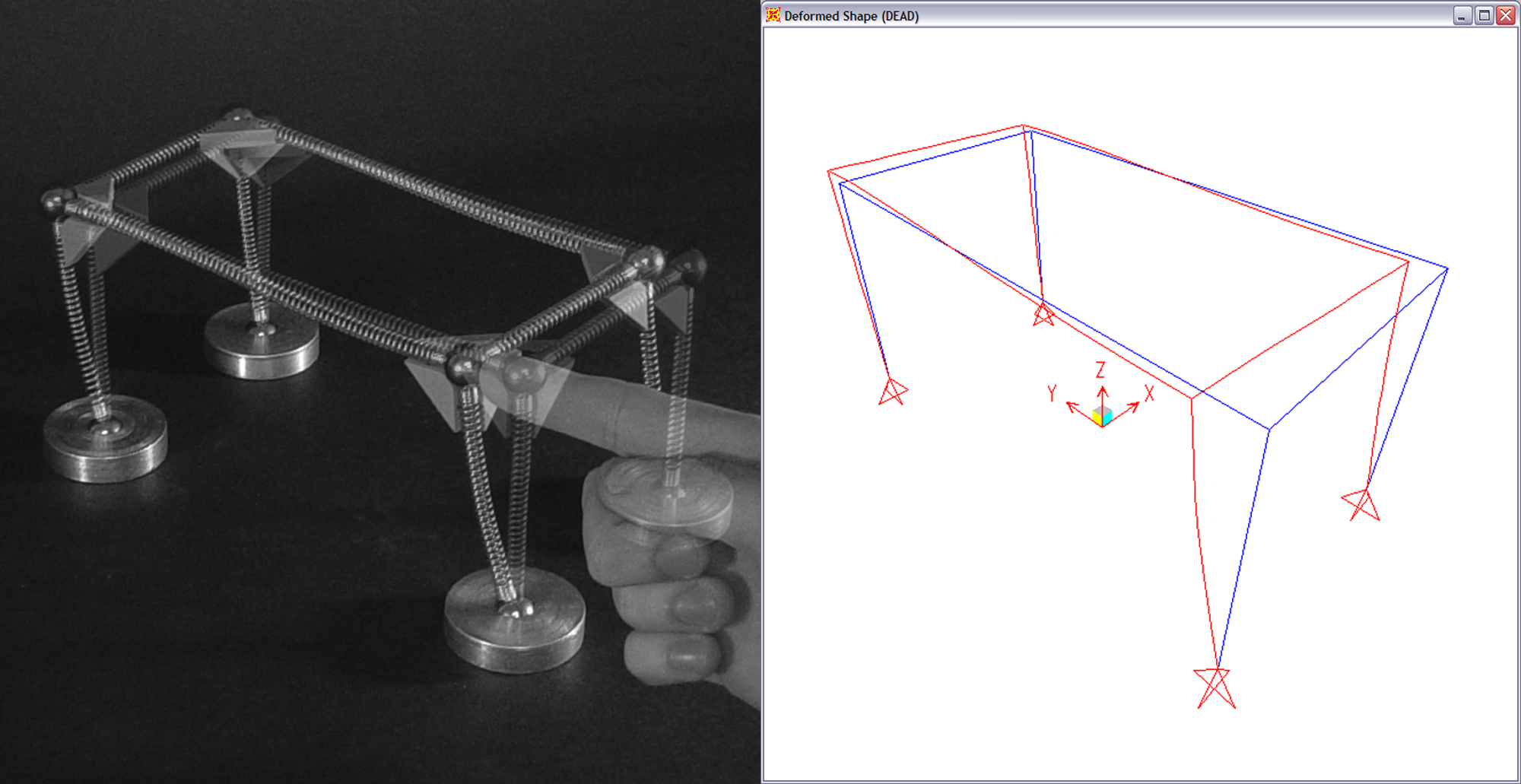

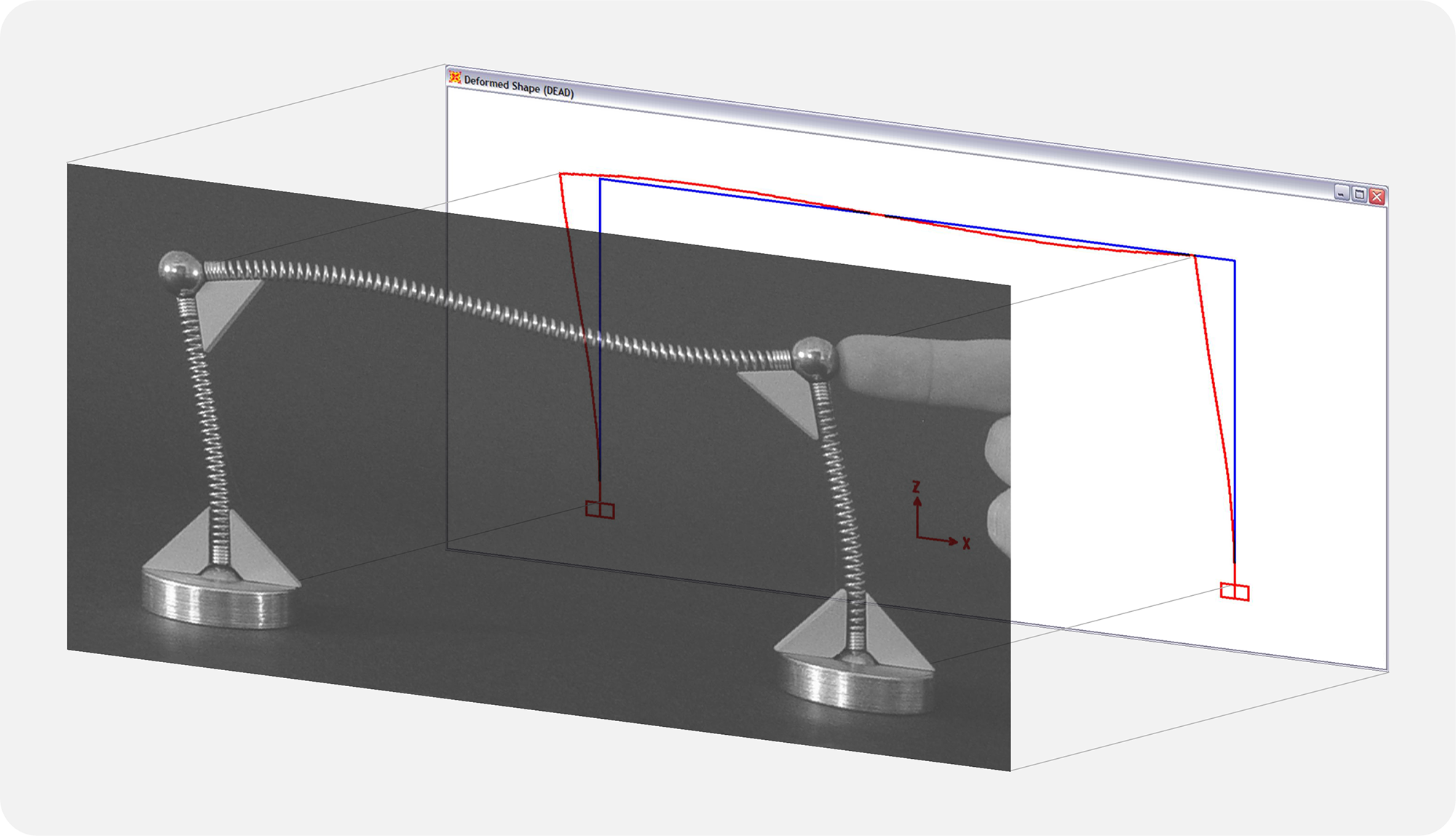

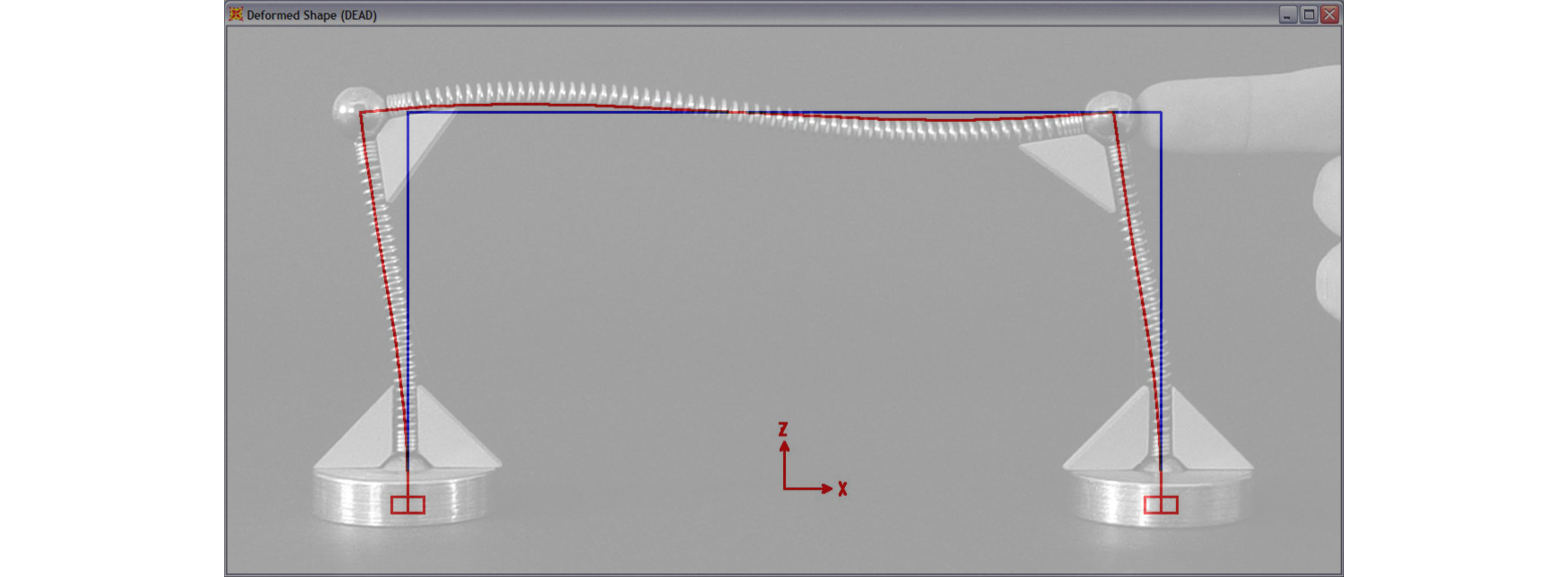

Deformed Shape

Theoretical Model

Deformed Shape

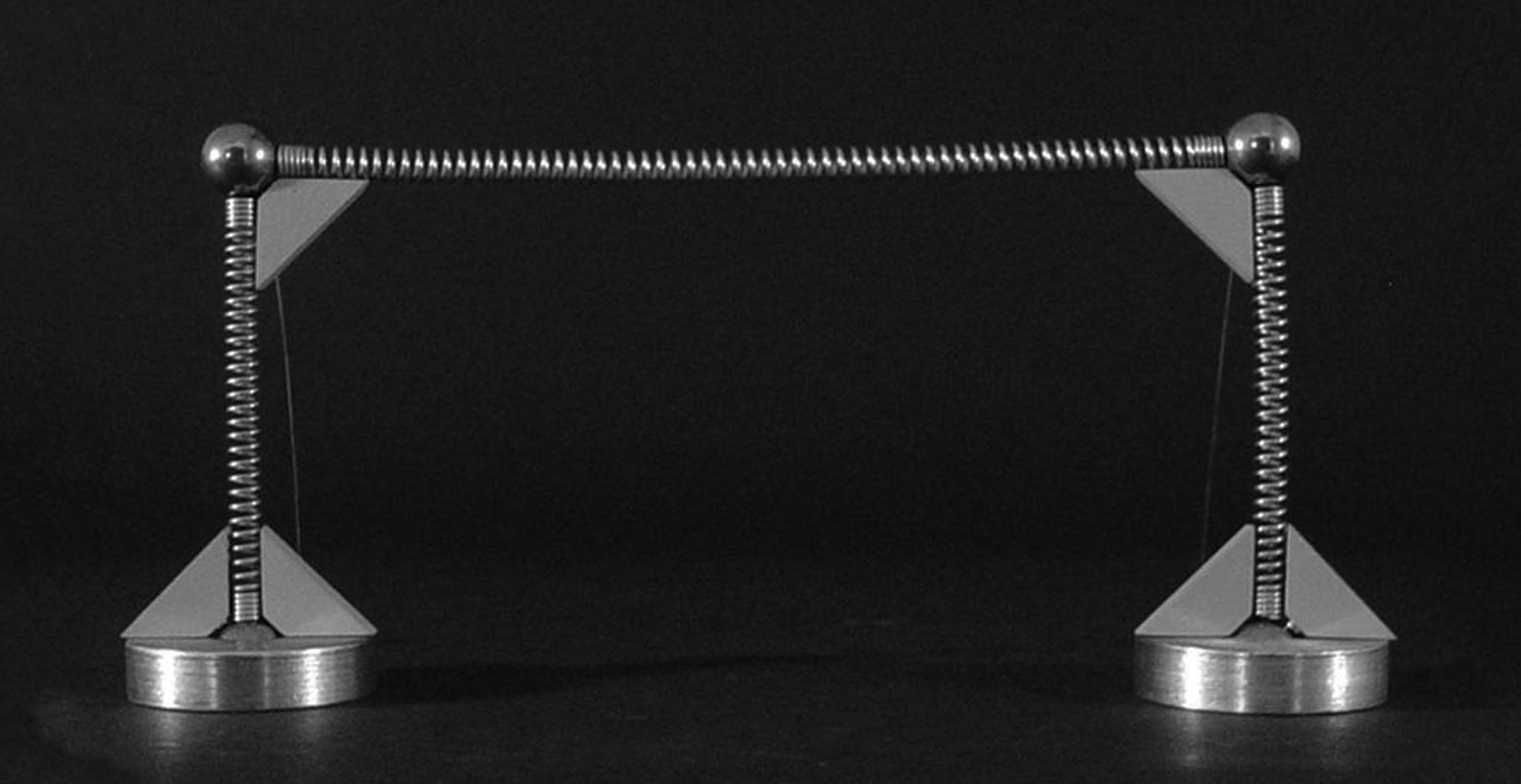

Mola Structural Model

Scientifically Validated System

To learn more, download the PDF file with the complete research, including all results and detailed analysis.

Available in Portuguese and English versions.

The scientific validation of Mola Structural System has been one of our top priorities since day one of product development. We recognized that although the behavior of Mola was intuitively similar to real structures, it was important to ensure that the model could be effectively used as a teaching tool for qualitative analysis.

After all, Mola not only enhances learning in engineering and architecture classrooms but also serves as a powerful design tool for professional offices, allowing the simulation of real projects, and facilitating the design process.

Mola’s versatility, enabling the assembly of a wide variety of structural systems, further drove the need for its validation. It was essential to ensure that the model's behavior was consistent regardless of the structural system in question.

The scientific validation of Mola Structural System was conducted through a master's research study, concluded in 2008 at the Federal University of Ouro Preto, Brazil.

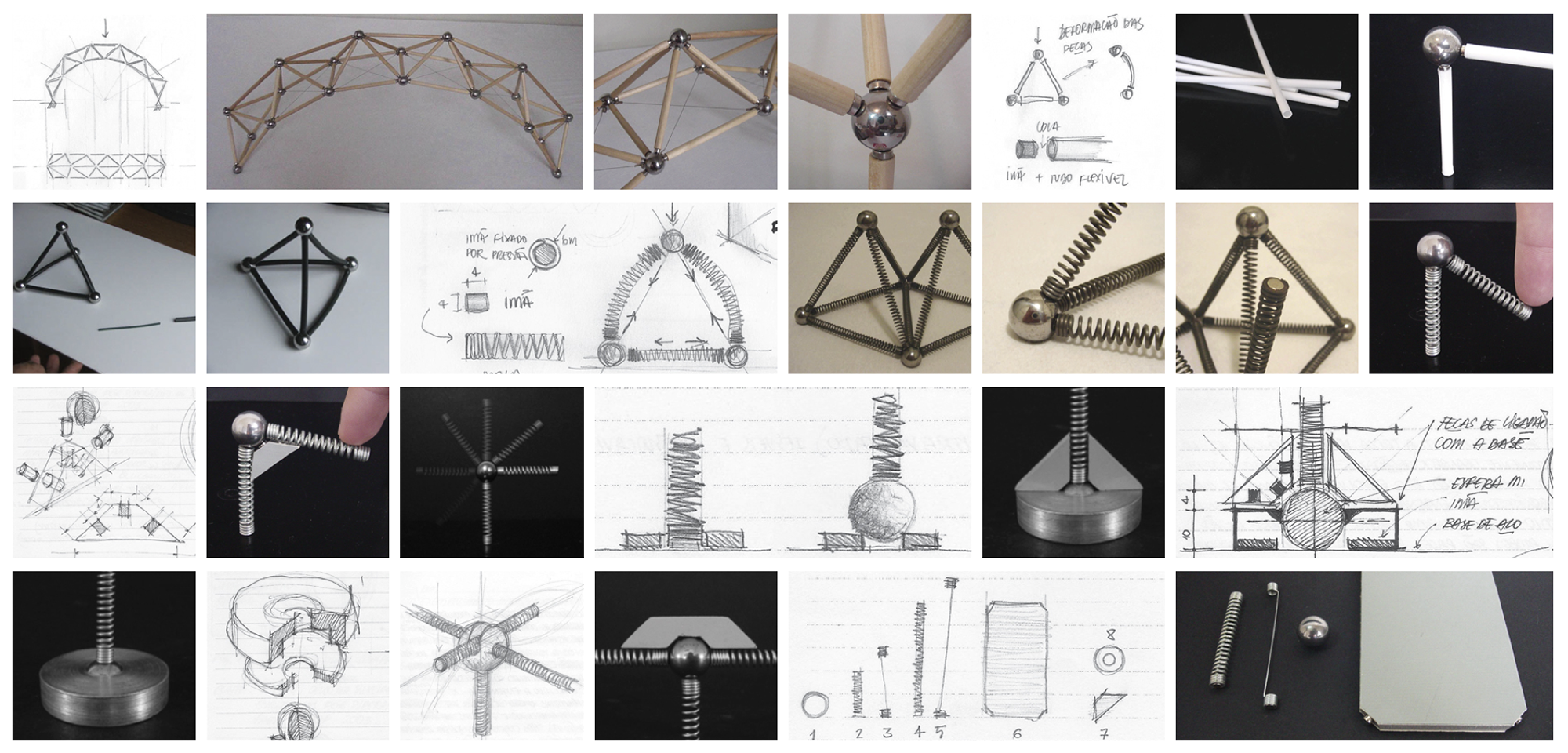

First prototypes and original sketches of Mola Structural System, developed during 2004 and 2006.

Download the PDF file to learn more about Mola's design process.

Validation

Methodology

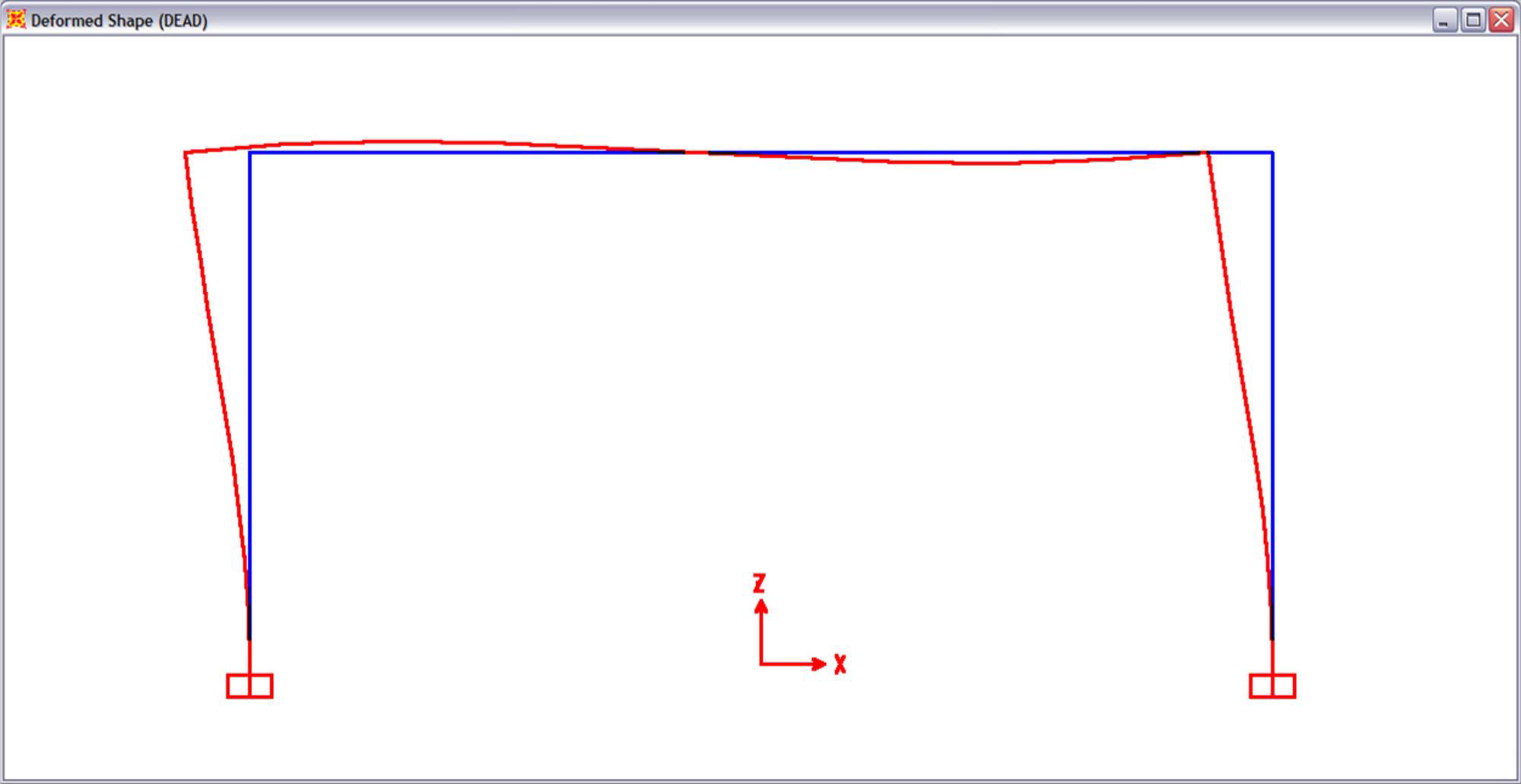

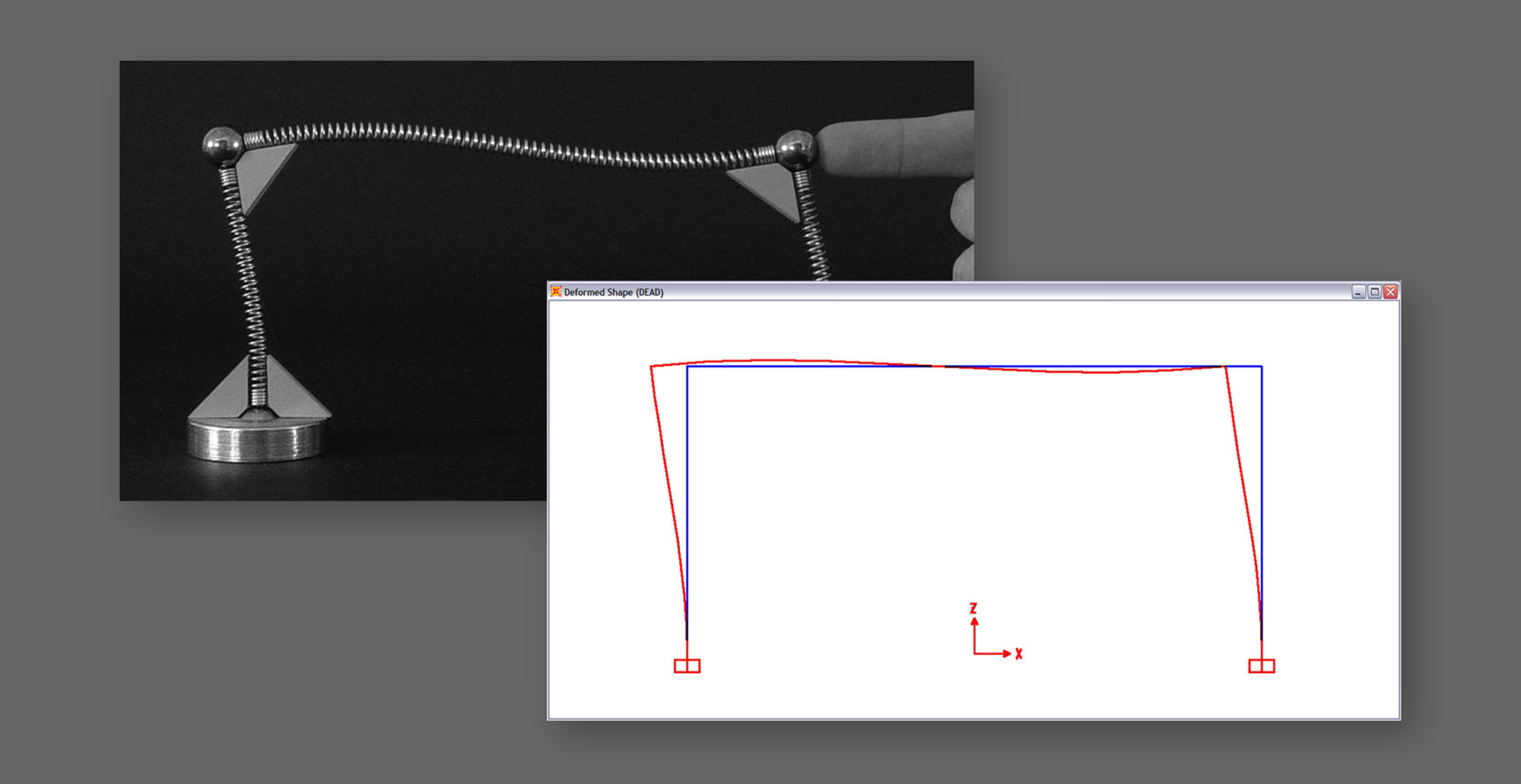

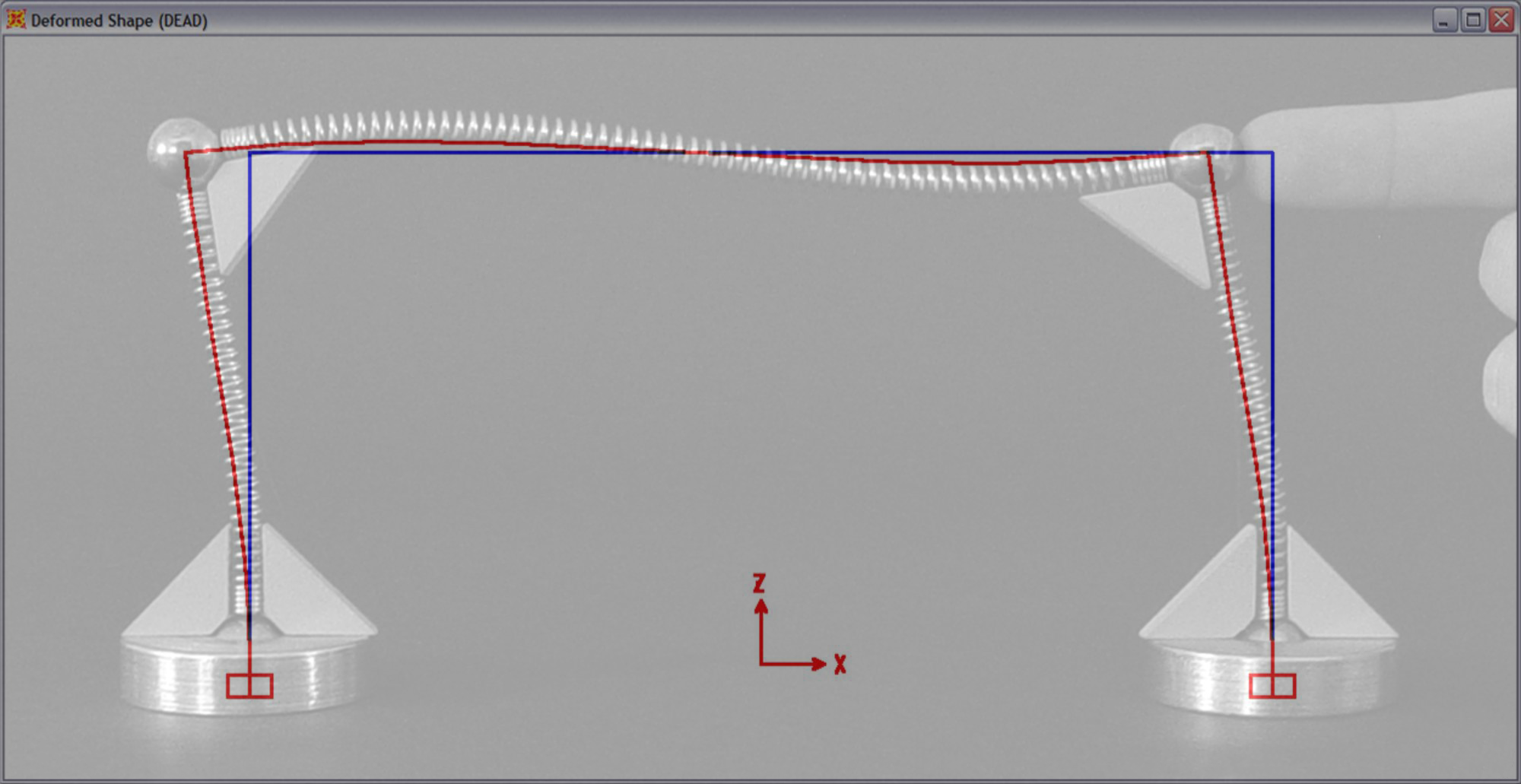

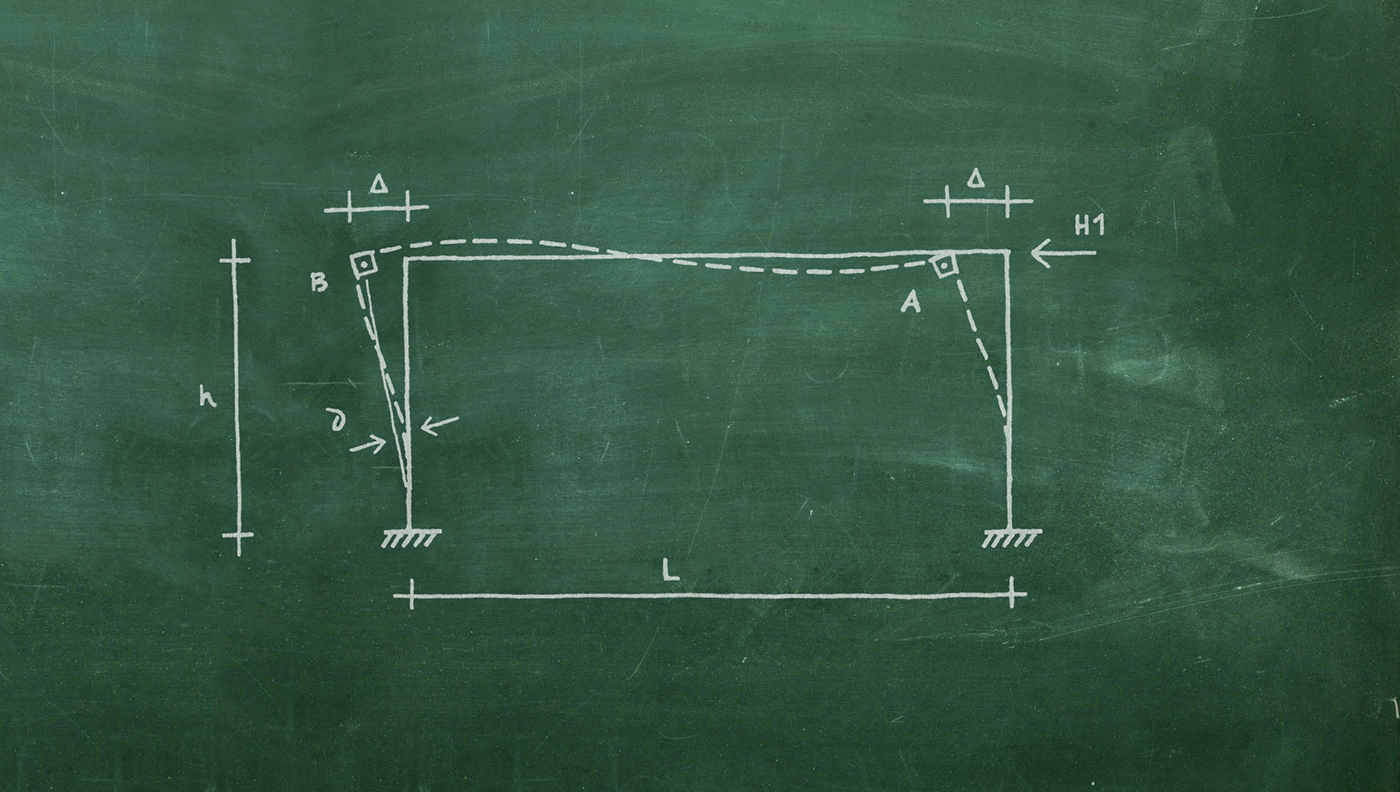

To validate the system, an experimental methodology was developed. It consists of comparing Mola's deformed shape with the deformed shape of real structures simulated using a structural analysis software (SAP2000).

This approach allowed for a direct comparison of Mola's behavior with the real structures, providing valuable insights into its reliability.

The experimental program developed for Mola's validation consists of five stages.

2. Model’s Deformed Shape Digitalization

In the second stage, a load is applied to the assembled structure, and the resulting deformation is registered through digital images. All model handling procedures, including the load application, are performed manually to replicate the real conditions of product use.

Validation

Results

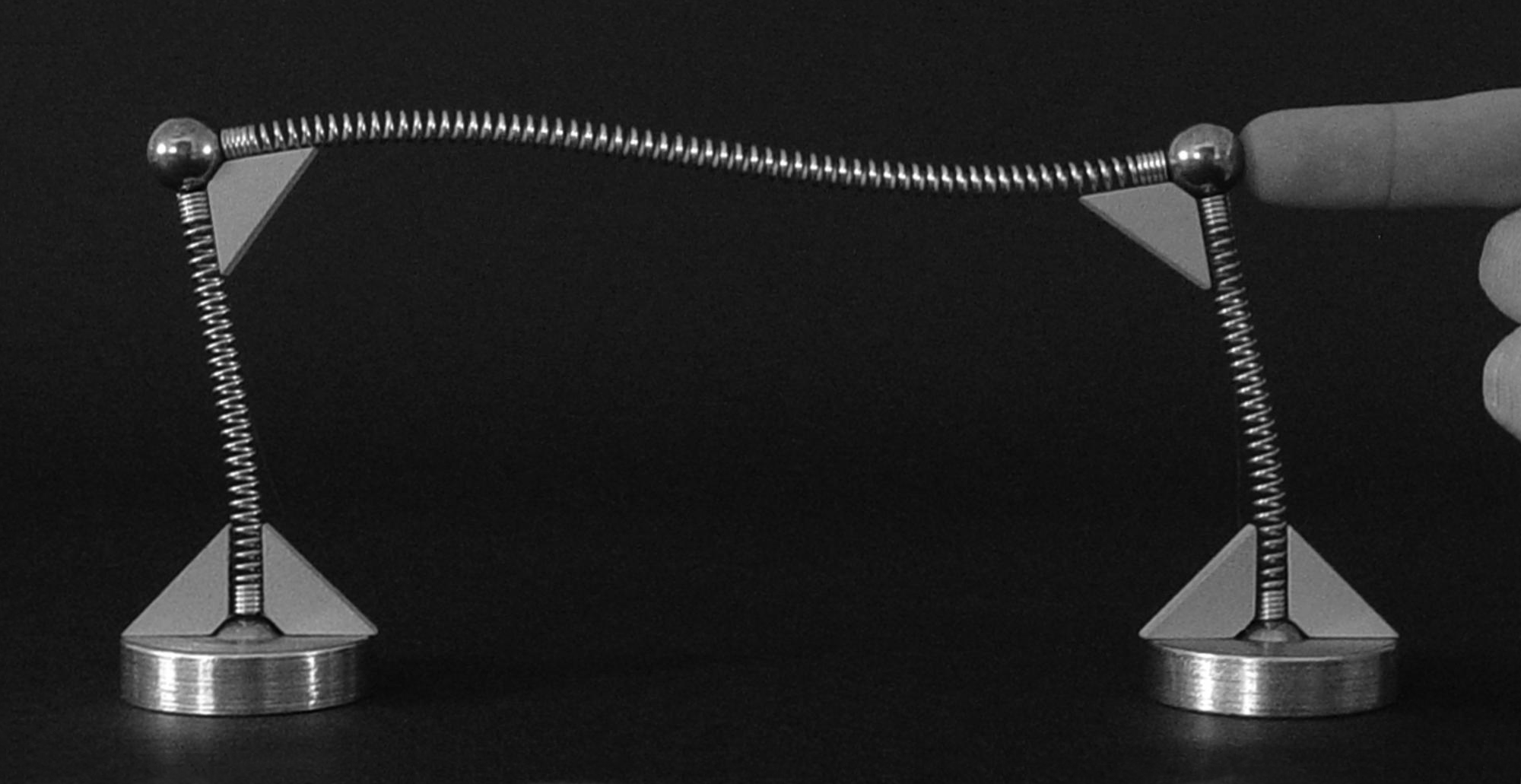

Over 40 experimental tests were conducted, covering everything from single elements to plane and spatial structural systems. Each structure studied was subjected to different boundary conditions and load cases, providing a comprehensive assessment of the model's performance.

Plane Frame

Rigid conections and horizontal load.

Mola's

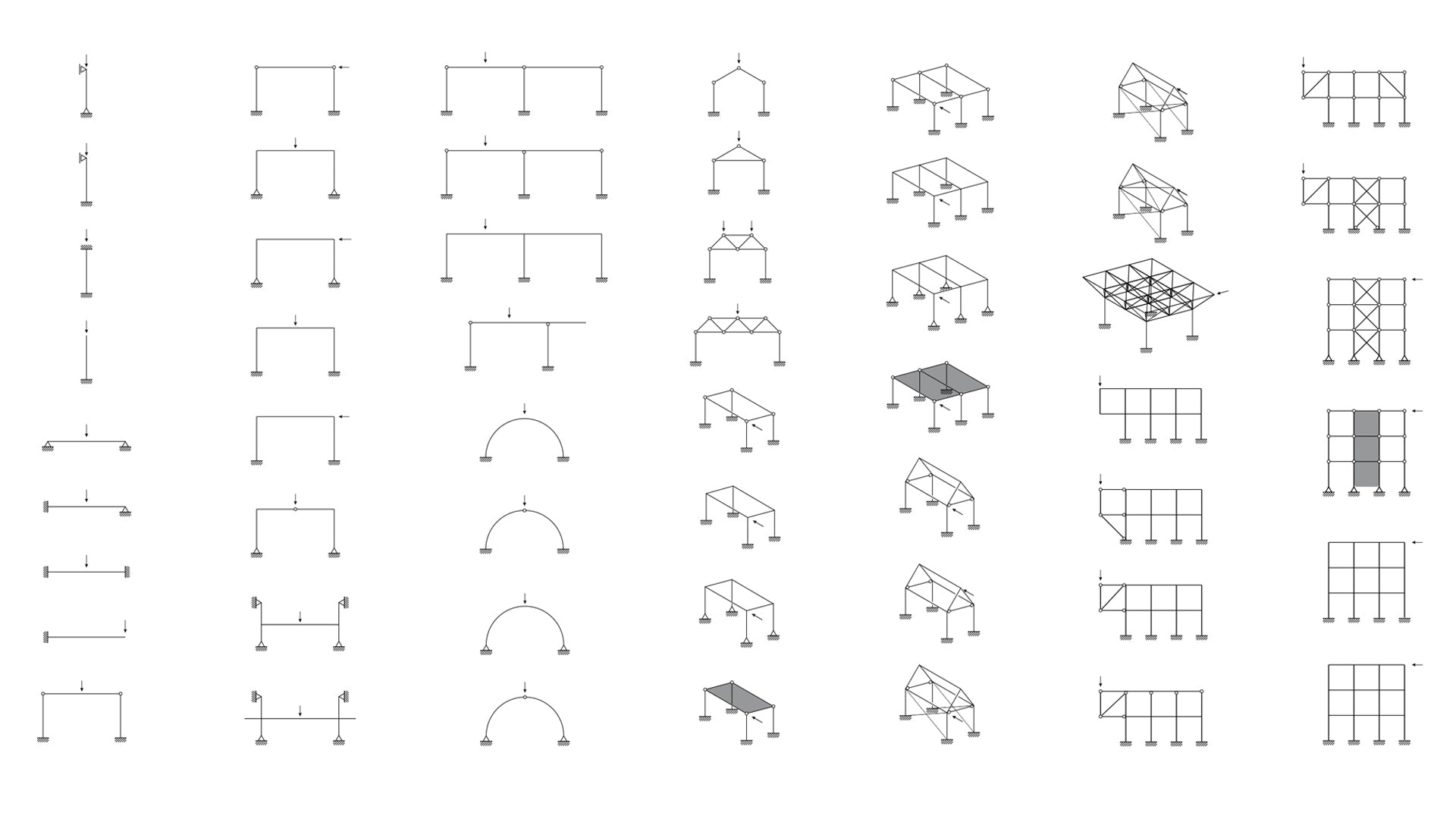

Versatility

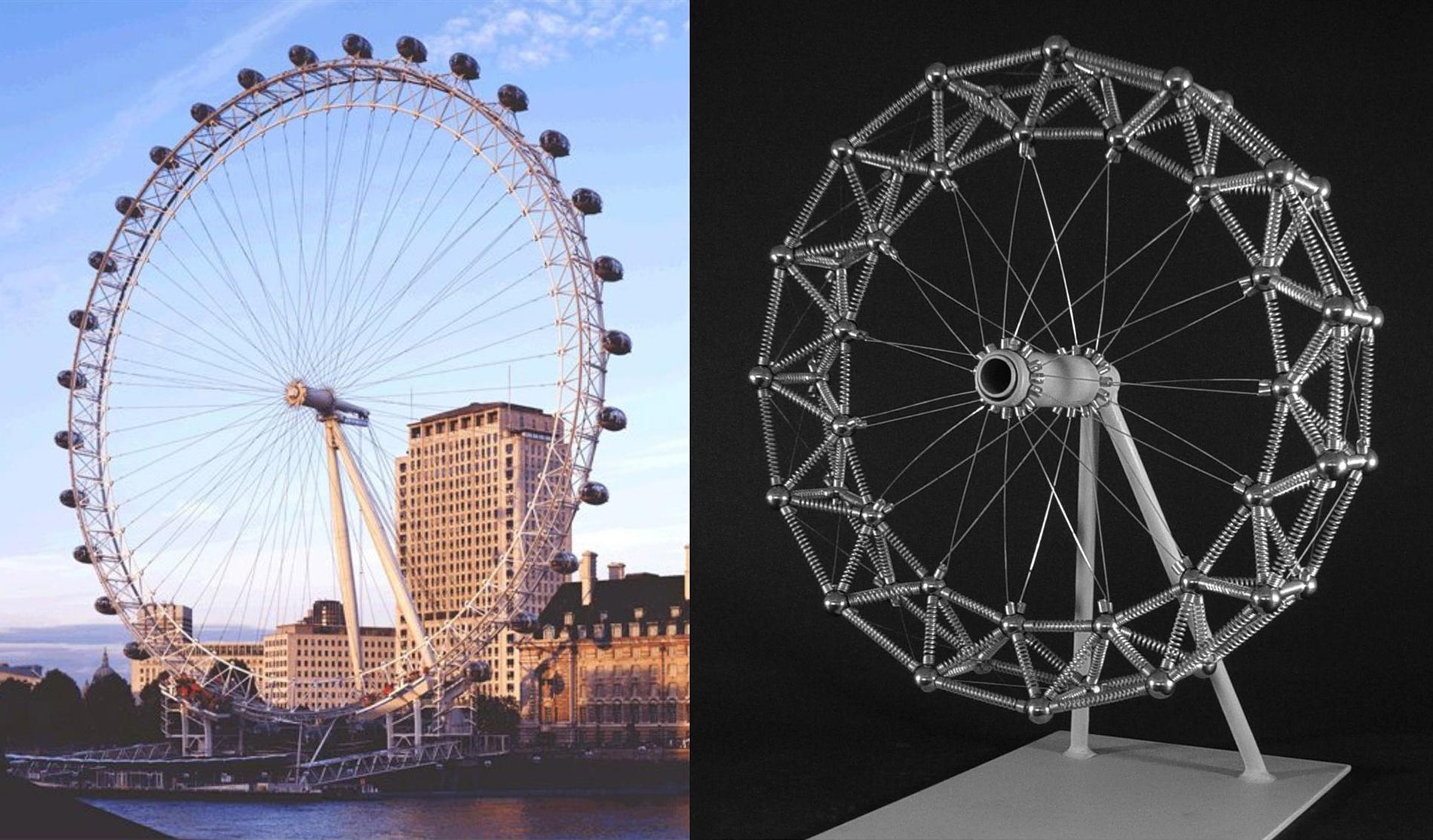

In addition to validating the behavior of Mola, the research also presents a sequence of structural systems assembled with the model, reproducing real structures.

This practical approach not only reinforces the validity of the product as an effective educational tool but also highlights its applicability in different contexts, from academic environments to professional projects.

Validation

Conclusion

The scientific validation of Mola Structural System for qualitative simulation of structures represents a significant milestone in the product's development and the application of the model as an educational and professional tool.

The research was crucial in ensuring the credibility and effectiveness of the product. It also demonstrates our commitment to providing reliable and quality products.

To learn more, download the PDF file with the complete research, including all results and detailed analysis, available in Portuguese and English versions.

Explore our products line-up

A new way to study, teach and design structural systems