The scientific validation was a crucial moment in Mola's path. From that point on, it was possible to transform an idea into a product with its own niche in both the academic and professional frameworks, and that not only keeps on contributing to the teaching and learning of structures, but also favors the establishment of a market for this type of educational and structural design tool.

The initial idea for Mola arose during a postgraduate program in architecture, when the product’s creator and founder of the company realized, as a student, how abstract the approach to structural subjects is. The challenge was to create something that could demonstrate in a visual and tactile manner the behavior of architectural structures, a knowledge that is fundamentally necessary for every engineer and architect, specially when conceiving a new building. Taking advantage of what we can perceive when using our hands (opposed to what we can learn when exclusively listening and observing), Mola’s pieces were thought out and designed with specific materials that shed light onto subtle structural deformations, making them noticeable to the unaided eye.

Since the beginning of the product’s development, its scientific validation has always been a priority. It was known that, even though Mola’s behavior is intuitively similar to real structures, it was important to guarantee that the model could be utilized efficiently as a teaching tool and also as a structural analysis tool. After all, Mola not only boosts knowledge inside architecture and civil engineering classrooms, it also works as an invaluable tool for professional offices, allowing real structures to be simulated, and, therefore, facilitating the design process.

The model’s versatility enables the assembly of a wide variety of structural systems, which further emphasizes the necessity of validating it scientifically. It was essential to make sure that the model’s behavior was consistent, regardless of what structural system was being analyzed.

Validation

Mola’s scientific validation was carried out through a Master’s research named “Qualitative structural model for pre-evaluating metallic structures’ behavior”, and was concluded in 2008, in the Federal University of Ouro Preto, in Brazil.

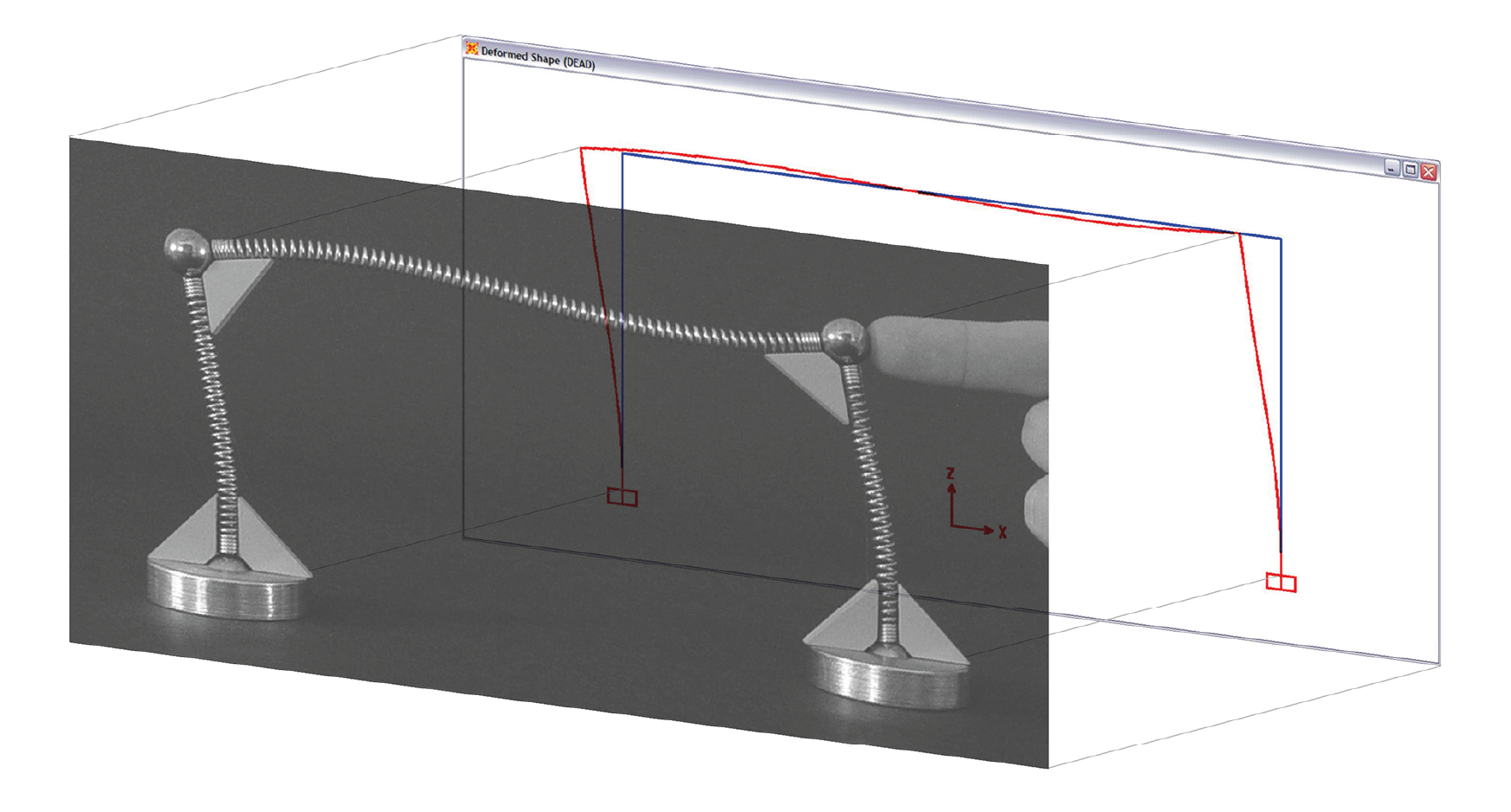

With the intention of validating the model, an experimental methodology was implemented, where the physical model’s deformations were compared to those shown by the SAP2000 software’s output, after creating the same structure within the computational program. This approach allowed for a direct and objective comparison between the model’s behavior and real structures, while providing important insights about its reliability.

Over 40 experiments were analyzed, encompassing isolated structural elements and spatial structural systems. Each structure was subjected to different boundary conditions and loadings, offering a comprehensive evaluation of the model’s performance.

Experimental program

The experimental methodology developed to validate the model is composed by five steps:-

Assembling the structure with the Physical Model:

-

Digitalization of the model’s deformation:

-

Computer simulation:

-

Preparation and overlaying of the images:

-

Results analysis:

Results

Mola proved to be much more precise than what was expected initially. The research’s results confirmed that the physical model shows very similar behavior to the analyzed structures, thus validating its effectiveness as a tool for teaching and also for analyzing architectural structures in a qualitative manner.

Versatility

Besides validating Mola’s behavior, the research also presents a sequence of structural systems assembled with the model, replicating real structures. This practical approach not only reinforces the product’s credibility as an effective teaching tool, but also highlights its applicability in different contexts, from academic ambients to professional projects.

Conclusion

Mola’s scientific validation for emulating structures in a qualitative manner represents a significant milestone in the product’s development and in its use as an educational and professional tool.

Share:

The POLIS University's innovative approach to teaching structures